Summary

- Profile Type

- Technology offer

- POD Reference

- TOGB20240902008

- Term of Validity

- 2 September 2024 - 2 September 2025

- Company's Country

- United Kingdom

- Type of partnership

- Commercial agreement with technical assistance

- Targeted Countries

- All countries

Contact the EEN partner nearest to you for more information.

Find my local partner

General information

- Short Summary

- A UK small company has proven in the lab and patented metal-free, halide-free surface finishing that is grown in a conventional plasma chamber. The investment pays for itself quickly as the need for water, energy and water treatment disappears. PCB manufacturers are sought to bring the TRL up under collaborative R&D funding and then adopt under license.

- Full Description

-

A PCB surface finish is an intermetallic joint between the bare copper of the solderable area of the PCB and the components. The finish is needed since copper is susceptible to oxidation. A variety of finish types exist involving coatings made with chemical or electrochemical methods, depositing for example precious metals, tin or nickel.

It is no secret that this finishing step is hardly eco-friendly, involving very large quantities of water, energy for warming the water and downstream treatment plant. As the investment cycles in the industry are long, adoption of eco-friendly methods is being pushed back.

A UK SME now offers novel (patent pending) chemistry for PCB surface finishing that gets grown in readily available plasma chambers. The investment will pay for itself in a year because it obviates the water, saves energy and water treatment consumables.

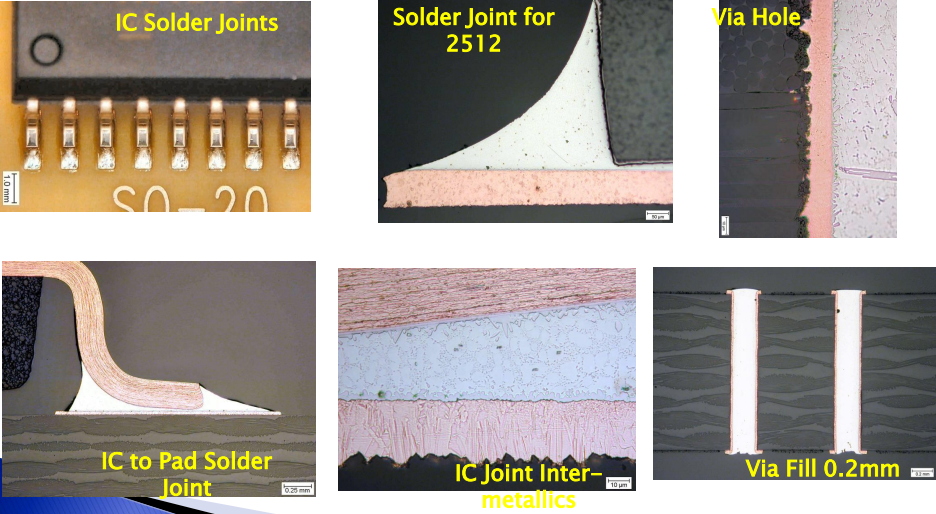

It has been proven in the lab that it works (see some examples in the Picture). Furthermore, it outperforms conventional methods in corrosion tests.

The chemistry is metal-free and halide-free so that it requires no additional step in the recycling process at end of life. The method suits both low volume and high volume manufacturing.

The UK company wishes to start technical cooperation with PCB manufacturers to validate the method in simulated or real industrial settings. The preferred financing scheme is EU collaborative R&D schemes. - Advantages and Innovations

-

The chemistry is novel (patent pending) but not difficult to scale.

The advantage is a combination of large savings in energy and water and low running costs. - Stage of Development

- Available for demonstration

- Sustainable Development Goals

- Goal 9: Industry, Innovation and Infrastructure

- IPR status

- IPR applied but not yet granted

Partner Sought

- Expected Role of a Partner

-

• Type of Partner Sought: Industry.

• Specific Activity of Partner Sought: PCB manufacturers.

• Role of Partner Sought: to engage in joint technical development, funded by collaborative R&D grants. In the event of (most likely) successful results the partner can adopt the technology under license. - Type and Size of Partner

- SME 11-49

- Big company

- SME 50 - 249

- Type of partnership

- Commercial agreement with technical assistance

Dissemination

- Technology keywords

- 05001004 - Organic Chemistry

- 05001003 - Inorganic Chemistry

- Market keywords

- 03001007 - Circuit boards

- Targeted countries

- All countries