Summary

- Profile Type

- Business Offer

- POD Reference

- BOUA20250502006

- Term of Validity

- 2 May 2025 - 2 May 2026

- Company's Country

- Ukraine

- Type of partnership

- Commercial agreement

- Targeted Countries

- All countries

Contact the EEN partner nearest to you for more information.

Find my local partner

General information

- Short Summary

- The Ukrainian company is engaged in the manufacture of powder metallurgy parts from powders based on iron, bronze and copper. The company was established in 1990 in the North of Ukraine. They can design and manufacture all the elements in accordance with the client’s individual requirements. The company offers manufacturing agreements to potential partners.

- Full Description

-

The Ukrainian company focuses on the production of powder metallurgy parts from powders based on iron, bronze and copper. At its own facilities, the enterprise produces large batches of structural, electrical and general industrial parts. Production capacity is up to 800,000 parts per month. Fields of application: automobile manufacturing, machine tool manufacturing, instrument manufacturing, electrical engineering, agricultural engineering, and railway transport.

Below are the products that SME manufactures on an ongoing basis:

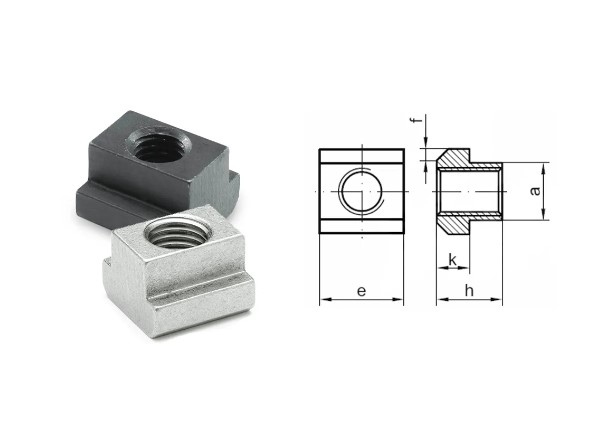

- Sliding bushings - production of bearings of several types: cylindrical, flanged, spherical from bronze and iron;

- Gears - a large variety of gears/tribes for automatic transmissions: sprockets, pulleys, gears, shafts, etc.;

- Mestizos - manufactured according to standards, a wide range of sizes and shapes;

- Frictions - all types of friction products for automatic transmissions and other mechanisms;

- Metal filters - effective filtration of solid particles, impurities, dirt, etc.;

- Structural steel parts - a wide selection of parts.

They are always ready to consider the possibility of manufacturing parts according to the client's drawing.

The technical potential of the enterprise is a park of press equipment with a capacity of 100, 160, 400 tons. Muffle furnace for sintering with a protective atmosphere.

Thermodiffusion galvanizing zone. Mechanical department for processing parts and manufacturing press tools, equipped with milling, turning, grinding, sharpening, drilling, threading machines and auxiliary equipment. Section of industrial washing and packing of parts. Electrical engineering laboratory.

The desired outcome of an international partnership: expanding sales network to the EU. - Advantages and Innovations

-

- high accuracy of the shape and size of the part;

- the possibility of manufacturing complex geometric shapes and structures;

- high strength and hardness of finished parts;

- minimal loss of material, as the powder can be used effectively;

- the ability to control the composition and properties of the part by using different types of powders and additional components. - Stage of Development

- Already on the market

- Sustainable Development Goals

- Goal 12: Responsible Consumption and Production

- IPR status

- No IPR applied

Partner Sought

- Expected Role of a Partner

-

The company offers manufacturing agreements for EU countries' partners of powder metallurgy parts from powders based on iron, bronze and copper according to the drawings of the customer.

For manufacturing agreements, the company is looking for SMEs to offer production services according to the potential partners' needs. The SME is open to acting as a manufacturer of powder metallurgy parts for companies that are interested in these products. - Type and Size of Partner

- SME 50 - 249

- SME 11-49

- Big company

- Type of partnership

- Commercial agreement

Dissemination

- Technology keywords

- 02007010 - Metals and Alloys

- Market keywords

- 09004008 - Other manufacturing (not elsewhere classified)

- Targeted countries

- All countries