- Network partners

- Sector group

-

Intelligent Energy

- Countries

-

FRANCE

On the French Côte d'Azur, halfway between the legendary beach towns of Cannes and Antibes, you do not just find tourists and movie stars. In the busy Sophia Antipolis science park, two engineers, Sabri Takali and Ahmed Kacem, are working hard on decarbonising Europe. They are the founders of Plenesys, a company that wants to change how we make hydrogen.

"We need to produce clean hydrogen at large scale, in a cheap way and with fewer costs," said Takali, a PhD graduate of Mines Paris. "Current processes, however, don’t allow us to do that."

Hydrogen might be one of the key technologies for a sustainable energy transition. This molecule could provide a clean alternative to fossil fuels and help us transition hard to decarbonise sectors that range from steel production to airplane travel. Hydrogen, however, has an Achilles heel: its production. Today, 95 % of all hydrogen is still produced in a polluting way.

Steam methane reforming (SMR) is a cheap way to produce hydrogen, but it results in emissions. Using natural gas in this chemical process to create hydrogen emits more than 10 kg of CO2 per kg of hydrogen produced. Another hydrogen production method is electrolysis. Here, hydrogen is created out of water and electricity. This process is cleaner than SMR but has several weaknesses. It uses large quantities of water and requires extensive energy to power the process. Today, most of that energy comes from fossil fuels. It can also be quite expensive.

The overriding disadvantages of current methods motivated Dr. Takali and Dr. Kacem to found Plenesys and develop a new way. Their method promises to combine the low cost and scalability of SMR with the sustainability of electrolysis using green energy at much lower electricity consumption.

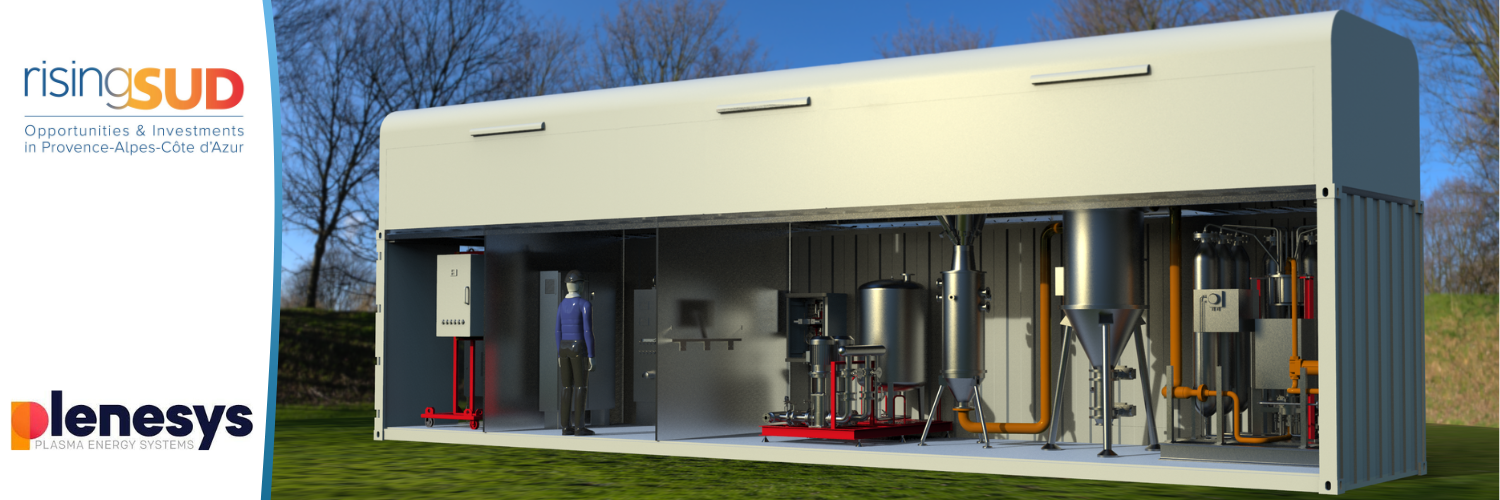

Plenesys’ process is called HyPlasma. Here they use plasma to transform methane into hydrogen, and the process offers carbon black as a side product, which is used in paints and tyres. They break down methane, without emitting CO2. This is done through plasma torch technology developed by Plenesys. This procedure can produce clean hydrogen and different types of carbon products, while being comparable in cost to technologies such as SMR and 3 to 5 times less than electrolysis. HyPlasma can also produce directly compressed hydrogen, saving valuable costs.

Accelerator

Today Plenesys employs around 13 people but hopes to grow to 17 by the end of the year. The company has made its first sales of equipment and has signed partnerships with large industrial companies. To get here, Plenesys’ participation in the European Innovation Council’s (EIC) Accelerator was crucial. They were able to advance technologically. But it also made the company more attractive to customers and investors.

The Enterprise Europe Network provided key assistance that enabled them to enter the EIC programme. Local partner risingSUD acted as their point of contact in the south of France. "We have been accompanied by risingSUD since the very beginning of our journey," said Dr. Kacem. "They have offered us very valuable assistance, enhancing our contacts in Europe through special programmes and introductions to important stakeholders. Their assistance in the EIC Accelerator application has been crucial, especially for the oral phase."

The team at risingSUD first got in touch with Plenesys around 2022. At the time, Plenesys was in an early stage of its development. It was small, and still heavily focused on technology development. It had won some French technology contests such as iLab and iNov. But it needed financial support to accelerate its development and get itself ready for industrial adoption. Which is why Nicolas Chéhanne of risingSUD suggested that Plenesys apply for the EIC Accelerator, but also realised that it is one of the most competitive EU programmes. So they helped them with their application, such as the proposal draft and preparation of the oral pitch.

"We proposed and explained the EIC Accelerator to them when we first spotted them," said Chéhanne. "Plenesys works on disruptive technologies, so we felt they were an ideal match for the EIC Accelerator."

In addition, Plenesys developed some business opportunities through the Enterprise Europe Network in Germany. Participation in these programmes significantly sped up the development of the company. It is currently aiming to deploy its first technology proof-of-concepts by the beginning of 2026. A fundraising round is also on the agenda.

Meanwhile, Plenesys are continuing to grow their company on the Côte d'Azur. "Hydrogen has a lot of promise for the south of France," said Dr. Takali. "It hosts many industries that will use hydrogen for decarbonisation, such as the chemical industry and steel production around Marseille. However, to do so we need to be able to produce it at scale, in a clean way that is also cost effective. We hope we can help them do that."