Summary

- Profile Type

- Technology offer

- POD Reference

- TOHU20240429007

- Term of Validity

- 29 April 2024 - 29 April 2026

- Company's Country

- Hungary

- Type of partnership

- Research and development cooperation agreement

- Investment agreement

- Commercial agreement with technical assistance

- Targeted Countries

- All countries

Contact the EEN partner nearest to you for more information.

Find my local partner

General information

- Short Summary

- A Hungarian technology transfer agency is offering its technology, an advanced expanded polystyrene (EPS) lightweight concrete structure. Additive composition is the production of lightweight concrete containing polystyrene beads, a method of producing the composition, and the application of a brand new, innovation to provide a response to the need for environmentally conscious, cost-effective, and technologically advanced building materials. License, investment, and R&D partners are sought.

- Full Description

-

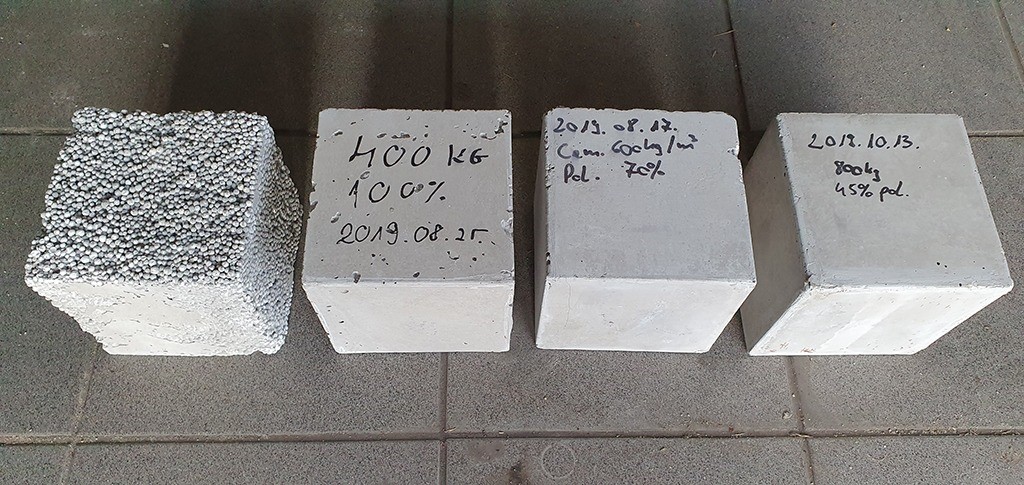

Additive composition for the production of lightweight concrete containing polystyrene beads, a method for producing the composition (concrete and polystyrene beads) and helping with its application.

The main solution is to expand the range of building industry additives and building materials. The composite material offered by the Hungarian company has significantly improved properties compared to the traditional building materials already available.

There is an emphasis on an environmentally conscious manufacturing technology, admission and application costs, and technological characteristics.

„Own-material doping" technology": polystyrene waste is dissolved in a solvent mixture, after which the solution is reacted with various organic and inorganic materials, catalyst compounds, and a multicomponent resin mixture to form a special complex compound with polystyrene content.

By separating the residues and waste products produced during the process, the constituents can be reused, and the by-products can be used as raw materials in other areas of the industry.

The primary application of the technology is in the production of lightweight concrete and building blocks. However, its versatility allows for a wide range of applications, including monolithic structures, masonry and block elements, and panel elements. The technology enables the creation of structures with excellent thermal insulation, fire resistance, and load-bearing capacity, making it suitable for various construction projects. Additionally, the use of plastic waste as construction material opens up opportunities for recycling and waste management in the construction industry.

The technology offers numerous benefits to customers. For manufacturers, it presents an opportunity to produce environmentally friendly and cost-effective building materials, tapping into a growing market demand for sustainable construction solutions. Distributors can offer a unique and innovative product that meets industry standards and addresses the need for energy-efficient and durable construction materials. End-users benefit from the thermal insulation, fire resistance, and load-bearing capacity of structures built with this technology, leading to lower energy costs and increased comfort. Overall, the technology promotes sustainability, reduces environmental impact, and offers economic benefits to all stakeholders involved in the construction industry.

The company is actively looking for potential license partners and is also interested in investments and joint R&D collaboration partnerships. - Advantages and Innovations

- This additive composition revolutionizes lightweight concrete production by enhancing its strength, durability, thermal insulation, and fire resistance. It is unique in its ability to incorporate expanded polystyrene (EPS) beads into the concrete, making it suitable even for load-bearing structures and monolithic constructions. The technology allows for the use of various plastic and rubber waste as construction materials, further contributing to sustainability. The resulting lightweight concrete has numerous advantages over traditional building materials, including lower weight, simpler manufacturing processes, and reduced costs compared to current solutions. Additionally, it meets industry standards for sound and thermal insulation, making it an ideal choice for environmentally conscious builders and developers.

- Stage of Development

- Lab tested

- Sustainable Development Goals

- Goal 9: Industry, Innovation and Infrastructure

- IPR status

- IPR granted

- IPR notes

- Protected by patents in Europe, China, the USA, and the Eurasian region

Partner Sought

- Expected Role of a Partner

-

The company is actively seeking to expand its network and capabilities through strategic partnerships and alliances. They are currently looking for license partners who can help them leverage their proprietary technologies in new markets. additionally, they are interested in connecting with potential investors who are keen on exploring the innovative and sustainable solutions that the company can offer in the sector.

Furthermore, they are eager to collaborate on research and development projects with partners who are committed to pushing the boundaries of what's possible in the industry. These collaborations will help to continue to innovate and maintain competitive edge, while also fostering mutual growth and success. - Type and Size of Partner

- Big company

- SME <=10

- R&D Institution

- SME 50 - 249

- University

- SME 11-49

- Other

- Type of partnership

- Research and development cooperation agreement

- Investment agreement

- Commercial agreement with technical assistance

Dissemination

- Technology keywords

- 02006001 - Materials, components and systems for construction

- 02006006 - Construction engineering (design, simulation)

- 02007005 - Composite materials

- 02006002 - Construction methods and equipment

- Market keywords

- 08005 - Other Industrial Products (not elsewhere classified)

- 08001015 - Other speciality materials

- 08001006 - Processes for working with plastics

- 08001018 - Polymer (plastics) materials

- 08001004 - Fibre-reinforced (plastic) composites

- Sector Groups Involved

- Construction

- Targeted countries

- All countries