Summary

- Profile Type

- Technology offer

- POD Reference

- TOHU20241010004

- Term of Validity

- 10 October 2024 - 10 October 2025

- Company's Country

- Hungary

- Type of partnership

- Investment agreement

- Commercial agreement with technical assistance

- Research and development cooperation agreement

- Targeted Countries

- All countries

Contact the EEN partner nearest to you for more information.

Find my local partner

General information

- Short Summary

-

A Hungarian technology transfer agency offers its technology.

The automated press brake tool change system uses a robot with a custom gripper to retrieve tools from a magazine positioned next to the press brake. It then moves them vertically into the press brake's tool holder with precision and speed, ensuring efficient and accurate tool placement.

The agency is looking for potential license partners or investors, R&D partners and technical assistance trade agreements. - Full Description

-

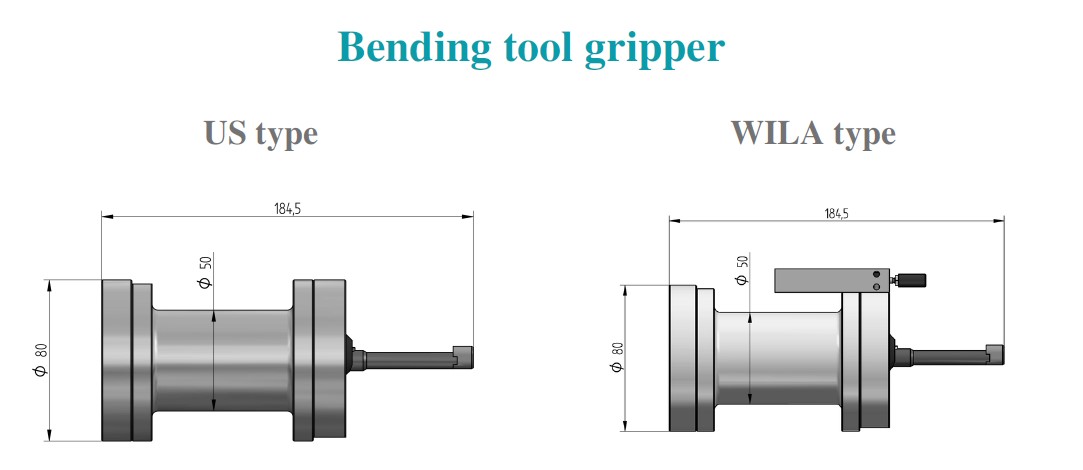

A Hungarian technology transfer agency is offering its technology, a system that enables automatic, universal, robot-controlled press brake tool change. Currently, apart from a few individual tool systems, 95% of the manufacturers of press brakes in the world use two type of tool clamping systems (also tool systems), the WILA and the US (Europe Standard or otherwise known as Amada-Promecam) systems. WILA is the world's leading tool system, but it is very expensive, costing three to five times as much as US system tools. Currently, only the WILA system has a robotic application in the world, the WILA company alone manufactures standard, commercially available grippers (press brake tool grippers) for robotic tool changing systems, as well as tools and accessories for the use of the system. Since 75% of the press brakes put into operation in the world are equipped with the US (Amada-Promecam) tool system, and press brake cells are also built with this tool system, but without an automatic bending tool changer, so this system also requires a solution for replacing the robotic press brake tools, because at the moment it is manually solved inaccurately and over a long period of time.

Technology specifications:

The main feature of the technology is its universality. But its simplicity, minimal maintenance, simple manufacturability, and low initial cost are significant. And it is not tied to any bending tool system.

The system also requires little and simple additional work during the production of press brake tools, so it only slightly increases their price. Even bending tools that have been in use for a long time can be converted to robotic grippers. And it can be used for both the WILA and US tool systems, but also for the Bystronic system, as well as for individual tools. In this way, we provide customers with a choice when purchasing the press brake cell.

Target users:

•Sheet Metal Companies

•Air Technology Companies

•Instrument Manufacturing Companies

•Machine Manufacturing Companies

•Components Manufacturing Companies

•Components Distribution Companies

The company seeks license partner, research and development cooperation agreements., investor, technical assistance trade agreements are sought. - Advantages and Innovations

-

Currently, only the WILA company in the world manufactures a commercial automatic press brake tool change system for robotic press brake cells. However, it can only handle its own WILA-Trumpf bending tools, but this press brake tool system is the most expensive.

The technology currently on offer is universal, not tied to any other system, much simpler and cheaper.

Customer benefits:

•The bending tool system can be chosen for the press brake cell. it is not tied to WILA alone.

•Changes press brake tools with high precision and speed (three times faster than manual replacement).

•The whole system is simple and cheap.

•Press brake tools are slightly more expensive than standard tools.

•Even existing bending tools can be converted to robotic handling. - Stage of Development

- Available for demonstration

- Sustainable Development Goals

- Goal 9: Industry, Innovation and Infrastructure

- IPR status

- Secret know-how

Partner Sought

- Expected Role of a Partner

-

The company is seeking partners from press brake manufacturers, robotic integrators, and tool system providers. Manufacturers of press brakes (especially those using US/Amada-Promecam, WILA, or Bystronic tool systems) would integrate the system into their products. Robotic integrators would be involved in adapting the automation technology to various press brake systems, ensuring seamless implementation of robotic tool changing. Tool system providers would collaborate in adjusting existing tools for compatibility with the robotic gripper system.

Potential partners would play key roles in adapting and integrating the universal robotic press brake tool change system into existing manufacturing environments, making it accessible to a broader market and enhancing precision and efficiency in production.

The Hungarian agency is looking for potential partnerships, including technical assistance trade agreements, license, investor agreements and research and development cooperation agreements. - Type and Size of Partner

- SME 11-49

- Other

- Big company

- SME 50 - 249

- SME <=10

- R&D Institution

- University

- Type of partnership

- Investment agreement

- Commercial agreement with technical assistance

- Research and development cooperation agreement

Dissemination

- Technology keywords

- 02003001 - Process automation

- Market keywords

- 03004003 - Other electronics related equipment

- 09003001 - Engineering services

- Targeted countries

- All countries