Summary

- Profile Type

- Technology offer

- POD Reference

- TOFI20231023003

- Term of Validity

- 6 November 2023 - 5 November 2025

- Company's Country

- Finland

- Type of partnership

- Investment agreement

- Targeted Countries

- Netherlands

- Germany

- Denmark

- Sweden

- Norway

Contact the EEN partner nearest to you for more information.

Find my local partner

General information

- Short Summary

-

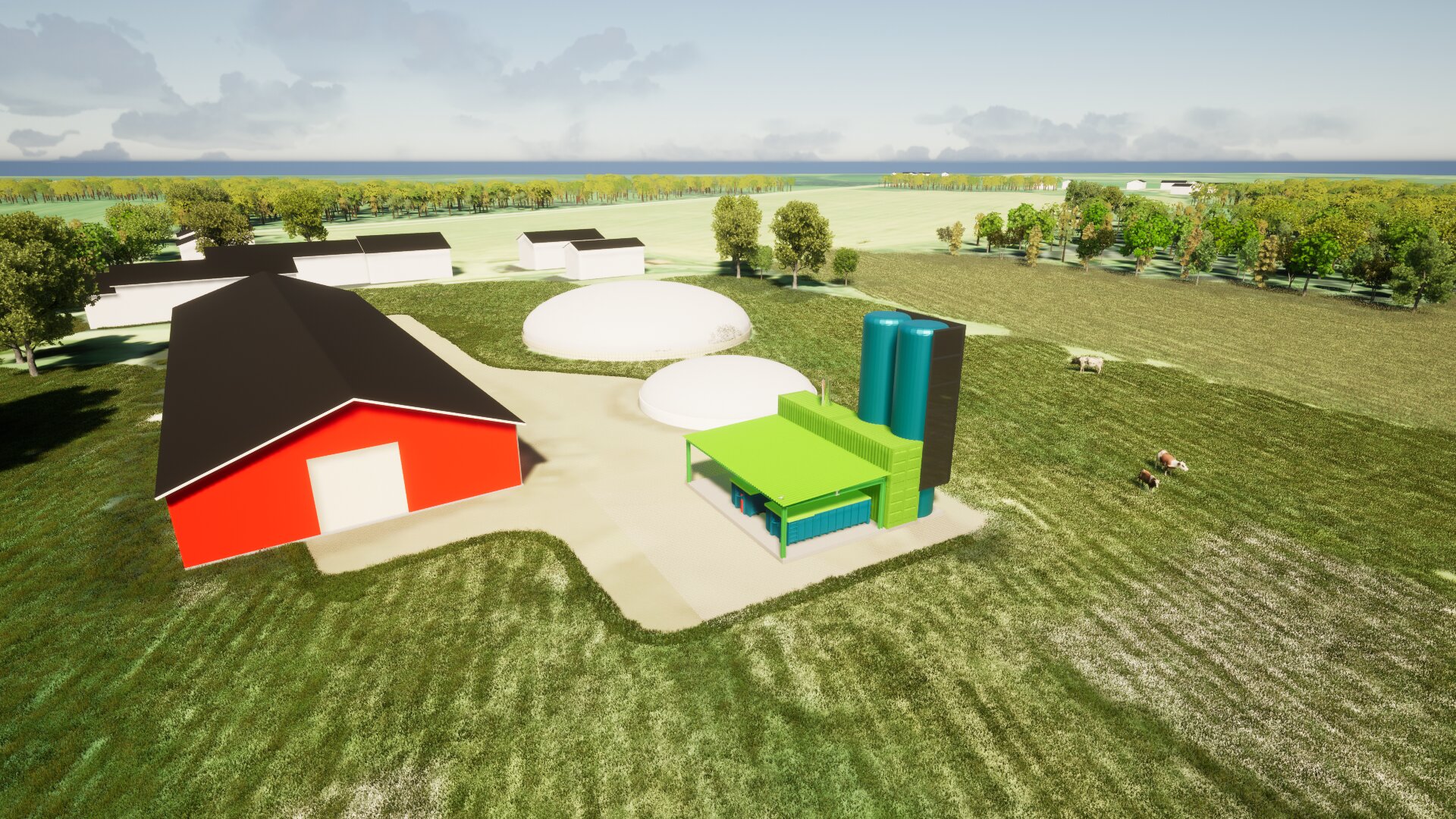

A Finnish company's innovation handles farm's organic side-streams and turns it into valuable bioproducts while cutting down greenhouse gases, chemical oxygen demand and ammonia emissions.

The company is currently looking for an investor / industrial partner in biogas industry in the Netherlands, Germany and Scandinavia. - Full Description

-

The most common technology used for processing manure and biogas production is the continuous stirred-tank reactor (CSTR). Current manure processing and biogas plant solutions in the dairy sector are intended for larger farms, namely those with over 200 head of cattle. The high investment costs of current biogas plants are related to the size of the large reactor, which is the most expensive component of the plant.

The backbone of the company's process innovation is the breakthrough bioreactor technology, called hybrid expanded granular sludge bed (HEGSB) reactors. Whereas conventional solutions handle the manure in a single, large reactor requiring a post-digester for high methane yield, the bioproduct plant handles both the liquid and solids of the manure separately. This is done to maximize the fermentation efficiency and to reduce the reactor volume to bring down costs and to prevent harmful emissions.

The innovation utilizes and transforms the farm's manure into valuable bioproducts, maximize biogas yield and reduce manure-based emissions utilizing:

-New-generation high-rate liquid bioreactor

-New-generation high-rate solid bioreactor

-Sterilized bedding production unit

-Automation system of the plant

-Ammonia capture system

-Integrated power source: solar panels.

The plant concept includes variations of processes utilized in different industries. These sub-processes include the following:

-Thermal treatment for production of sterilized manure

-Ammonia capture

-IoT, sensors, data

-Pretreatment of organic solids

The plant produces four types of bioproducts:

-Biogas

-Nitrogen-rich liquid fertilizer

-Phosphorus-rich dry fertilizer

-Sterilized bedding.

The concept is optimally suitable for dairy farms with 50–500 head of cattle. The plants are designed to be modular and therefore easily scalable with standardized parts used in construction and assembly. The equipment in the plant is mostly recycled and recyclable.

The plant concept has been developed for swine farms as well. Technically, the same concept is applicable for swine farms and they present a significant additional market segment for the solution. However, there are some differences in the process as, for example, sterilized bedding production is excluded. The process is highly scalable for swine farms, estimated to be able to handle 190 000 metric tons of swine manure per year.

The plant is considered a mono-manure plant without processing anything other than manure. However, other feedstocks can be utilized as well, since the technical concept allows

seamless integration with feed and pretreatment for solids.

The plant has several positive environmental effects on the farm. It can reduce the greenhouse gas emissions in manure handling, livestock feed production, electricity, fuel and heating. It can reduce eutrophication of the soil and leakage into nearby waterbodies. It can also reduce the ammonia emissions on the farm as well as the chemical oxygen demand (COD).

The plant concept has been piloted in the development project, where three farms were involved. The solution has reached technical readiness level TRL 6, after being validated in field tests on a working farm.

Next phase is the full-scale demonstration. It can be done in dairy or in swine farm. It can focus only on biogas, or it can utilize all the sub-processes and gain more bioproducts and reduce more emissions.

Expected durations of the full-scale demonstrations projects:

-Dairy, with all sub-processes, two years

-Dairy, biogas only, one year

-Swine, with all sub-processes, two years

-Swine, biogas one year

Expected duration includes:

-Basic and detailed engineering

-Procurement and construction

-Infrastructure and integration on the farm

-Installation of demonstration plant

-Demonstration plant testing and review

The company is currently looking for an investor / industrial partner in biogas industry in the Netherlands, Germany and Scandinavia. - Advantages and Innovations

-

The company's solution is a breakthrough process innovation, which significantly boosts process efficiency and reduces reactor size and cutting investment costs. The process throughput is 3–5 times faster, 10–15 percentage points more efficient and has a 30–35 % lower energy consumption than conventional plants. It handles all the farm's manure and turns it into four valuable bioproducts for the farm: biogas, dry phosphorus and liquid nitrogen optimized fertilizers, and sterilized bedding. The plant is a profitable solution for the company behind it as well.

The separation of manure into two bioreactors for the anaerobic digestion of liquid and solid fractions reduces the hydraulic retention time of liquid manure to 7 days instead of the 60 days typically needed and that of solids to 20 days instead of the typically required 60–100 days. This efficient process fully exploits the biomethane potential of the manure without further need for post- or co-digestion, while minimizing the organics and residual methane in the digestate. The process temperature is controlled at +30 °C, promoting the methanogen populations optimally growing at this temperature.

Company has carried out carbon footprint calculations and simulations regarding the plant. The simulation and calculations were executed by a widely known, independent third party. The simulation results showed that the manure handling GHGs decreased by 87% when a bioproduct plant was in operation.

Based on the estimations, the concept can reduce approximately 50% of the total manure-induced ammonia emissions by utilizing the bioproduct plant's multiple-step handling of nutrients and the integrated ammonia capturing sub-process.

Manure processing in the bioproduct plant reduces the measured COD of the liquid effluent in field application by 60% compared to raw sludge (measured average reduction during the two-year test period). - Stage of Development

- Available for demonstration

- Sustainable Development Goals

- Goal 11: Sustainable Cities and Communities

- IPR status

- Secret know-how

Partner Sought

- Expected Role of a Partner

-

The company wants to make the solution a reality in solving agriculture's current challenges.

The company can provide technical and commercial information to build the world's first farm-scale plant which is powered by next-generation, high-rate bioreactors. This includes:

-The industrial rights and assets

-All engineering data including Mass & Energy balance calculations and Piping & Instrumentation diagrams

-All cost data and concept information

-All data from the simulations and the experiments

-The company’s expertise

The company is currently looking for an investor/industrial partner (later “Partner”) and is willing to sell the innovation and the IPR rights and assets related to it.

Ideal Partner:

-Have expertise in biogas industry and understanding of the current biogas technologies

-Have financial ability and recourses to demonstrate the technology

-Have ability and networks to commercialize the technology

Ways of working:

-The company sells the IPR rights to the Partner and provide expertise

-The company and the Partner establish joint venture. The company brings IPR and expertise. The Partner brings human and capital recourses. Joint venture will perform full-scale demonstration. After this:

--The joint venture can commercialize the technology

--The company can sell the shares of the joint venture to the Partner

--The joint venture sells the innovation

The company encourages all interested parties and those who are capable of commercialization to contact them and discuss further possibilities regarding the innovation. - Type and Size of Partner

- Big company

- SME 11-49

- SME 50 - 249

- SME <=10

- Type of partnership

- Investment agreement

Dissemination

- Technology keywords

- 004006003 - Process optimisation, waste heat utilisation

- 06006001 - Biobased Materials

- 04006 - Biogas and anaerobic digestion (AD)

- 06006012 - Bioprocesses

- Market keywords

- 08004004 - Other pollution and recycling related

- 06003009 - Biomass and Biofuels

- Targeted countries

- Netherlands

- Germany

- Denmark

- Sweden

- Norway