Summary

- Profile Type

- Business request

- POD Reference

- BRFR20230726028

- Term of Validity

- 26 July 2023 - 25 July 2025

- Company's Country

- France

- Type of partnership

- Supplier agreement

- Targeted Countries

- South Korea

- Taiwan

- Japan

- Singapore

- China

Contact the EEN partner nearest to you for more information.

Find my local partner

General information

- Short Summary

- An innovative French SME has specialised in the use of local seaweed in gourmet dishes for high-end catering. The SME is looking for a supplier of industrial production line capable of separating, cutting, roasting, seasoning, counting and packaging Yaki Nori type dried sheets and seasoned snacks. Technical support is also required to set up and optimise the production line. A supplier agreement is sought with a long-term partner manufacturing food process production lines in Asia.

- Full Description

-

The French innovative SME creates and manufactures nutritional and gastronomic products based on local French macro-algae. Yaki Nori (also called sushi Nori, roasted nori/seaweed/laver sheet, Kim Nori, or roasted seaweed sheets) is used in cuisine for sushi, snacks, and garnishing purposes.

The company's vision is to provide customers with a wide selection of seaweed-based food products and snacks that not only taste good, but also offer nutritional value, making them a healthy alternative to the usual snacks.

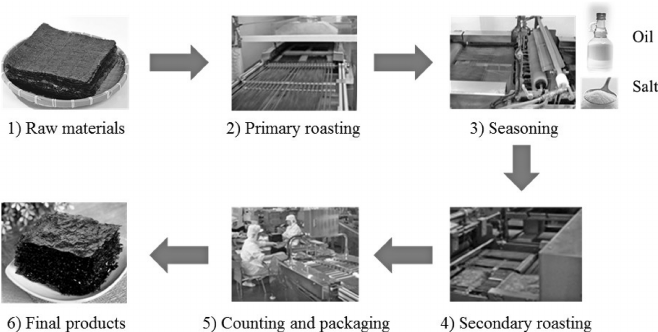

The SME is willing to implement a production line dedicated to roasting dried seaweed sheets, with a specific focus on Yaki Nori and other seasoned seaweed snacks. The implementation of this production line will enable the company to meet the increasing demand for innovative seaweed-based products and snacks on the European market.

The SME is looking for the entire production line to transform dried Nori-type sheets into roasted Nori-type sheets and seasoned seaweed snacks and packing in this format:

- sushi sheets (Nori-type): 10, 20, 50, 100 sheets per pack

- roasted and seasoned seaweed snacks: zipper bag with approx. 30-80 small sheets (about cut size of 40mmx10mm)

To achieve this, the need is a production line that can handle the entire process, from separating the dried sheets until final packaging of products.

The production line should be capable of processing approximately a minimum of 10,000 sheets per hour.

The production line should include the following capabilities and features:

1. Sheets separation: production line should have the ability to separate dried Nori-type sheets efficiently, ensuring a smooth and continuous workflow.

2. Cutting function: a mechanism to precisely cut portion sheets into desired snacks size, allowing for uniformity and consistent product quality.

3. Roasting equipment: production line should incorporate roasting machinery capable of roasting the sheets to achieve the desired texture and flavour.

4. Seasoning system: a seasoning system that can uniformly apply a variety of flavourings and seasonings to the grilled sheets, ensuring a delicious and consistent taste experience.

5. Counting and grouping: production line should include mechanisms for accurately counting the snacks and grouping them into desired quantities for packaging.

6. Packaging capability: system that can efficiently package snacks in individual portions or larger containers, ensuring product freshness and quality.

7. Quality control system: must include metal detectors and mechanism to detect any holes or defects in the sheets. This system should help ensure that snacks are free from contaminants and meet highest quality standards.

8. Technical support: supplier should provide training, technical expertise and assistance in importing, setting up and production line’s optimisation in our facility in France.

The French SME does not need process to dry the seaweed sheets.

A supplier agreement is being sought with a partner manufacturing industrial machinery in Asia. - Technical Specification or Expertise Sought

-

The technical requirements for a production line of this type typically include the following:

-Production capacity: the production line must have sufficient capacity to process at least 10,000 sheets per hour. This implies an appropriate processing speed to guarantee a constant throughput and the possibility of adapting the production capacity according to new expectations.

-Power: 220-380v needed

-Flexibility: a certain degree of flexibility is required to enable the production of different types of seaweed-based snacks. This may involve the ability to quickly change recipes, product shapes or sizes, or to adapt the production line to new requirements.

-Automation: the line must be equipped with automated systems to increase efficiency, reduce errors and guarantee regular production. This may include automated cutting, roasting, seasoning and packaging machines.

-Quality control: Technical expectations include the implementation of quality control systems throughout the production process. These may include metal detection devices to ensure the absence of contaminants, sheet thickness control systems, and systems for monitoring and rejecting defective products.

-Hygiene and safety: Particular attention must be paid to hygiene and food safety standards. The production line must be designed to facilitate cleaning and disinfection, using materials that comply with health regulations. Appropriate safety measures must also be put in place to protect workers and prevent accidents.

-Maintenance and technical assistance: It is essential that the supplier of the production line provides technical assistance, particularly with regard to the availability of spare parts, operator training and assistance in the event of technical problems. Ease of maintenance and the durability of the equipment are also important factors to consider. - Stage of Development

- Already on the market

- Sustainable Development Goals

- Goal 9: Industry, Innovation and Infrastructure

- Goal 2: Zero Hunger

- Goal 3: Good Health and Well-being

- Goal 14: Life Below Water

Partner Sought

- Expected Role of a Partner

-

Type of partner:

The partner must be a manufacturer of food process production line. The partner should supply the expected industrial machines and technical support.

Role of the partner:

The French company expects the partner to play a crucial role in the successful implementation of the industrial production tool.

The following expectations are expected from the partner:

-Provide technical information.

-Supply and help in delivering equipment.

-Installation and setup of the production tool.

-Technical training to the company's staff members responsible for operating and maintaining the production tool.

-Ongoing technical support to address any operational issues that may arise during the production process with remote support if required.

-Documentation and compliance: partner should assist the company in fulfilling all necessary documentation requirements related to the importation.

-After-Sales service: access to spare parts, regular maintenance recommendations, and ongoing support

Focus on certifications: production line should be certified to meet the CE standards; there will be a plus if the supplier should have experience and knowledge in obtaining the CE certification for similar machinery but it is not mandatory to supply. - Type and Size of Partner

- SME 50 - 249

- SME 11-49

- Big company

- SME <=10

- Type of partnership

- Supplier agreement

Dissemination

- Technology keywords

- 02003001 - Process automation

- 08001003 - Food Packaging / Handling

- 08001004 - Food Processing

- 08001005 - Food Technology

- 02002012 - Mixing (powder, etc.), separation (sorting, filtering)

- Market keywords

- 07005002 - Other restaurants

- 08005 - Other Industrial Products (not elsewhere classified)

- 07003002 - Health food

- 05008001 - Marine products

- 08003007 - Other industrial equipment and machinery

- Sector Groups Involved

- Agri-Food

- Targeted countries

- South Korea

- Taiwan

- Japan

- Singapore

- China