Summary

- Profile Type

- Technology offer

- POD Reference

- TODE20241126003

- Term of Validity

- 12 December 2024 - 12 December 2025

- Company's Country

- Germany

- Type of partnership

- Commercial agreement with technical assistance

- Investment agreement

- Targeted Countries

- All countries

Contact the EEN partner nearest to you for more information.

Find my local partner

General information

- Short Summary

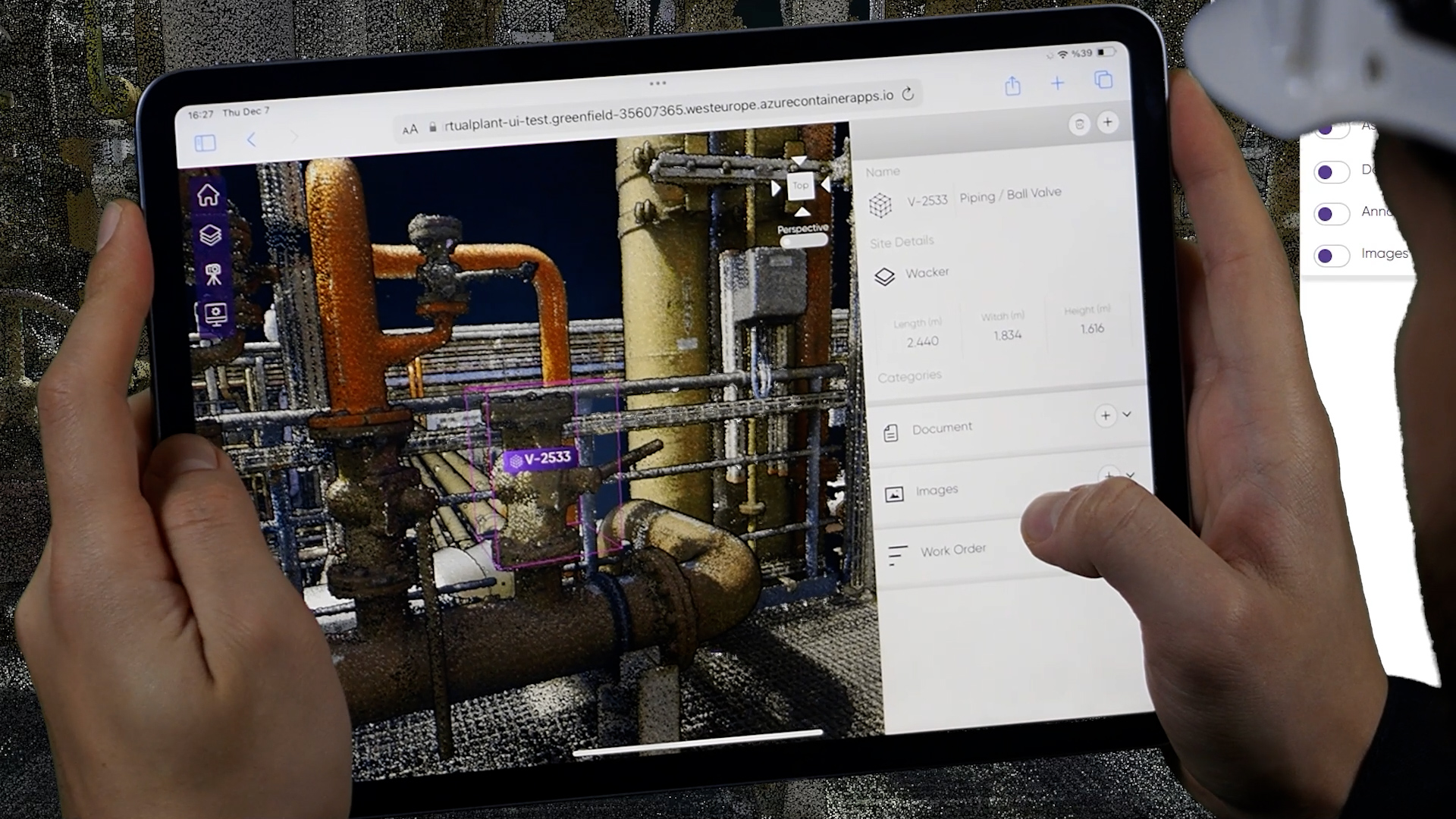

- A German company has developed a SaaS platform to allow the creation of digital twins of plants in process industries such as chemical, oil, and gas plants. The platform provides an industrial metaverse which enables all employees to access any plant-related information from anywhere at any time, for multiple purposes such as managing documents, plant assets, maintenance process, and many more. The company seeks potential users, and partners under a commercial or investment agreement.

- Full Description

-

This German company offers a suit of software solution and services that optimize operations of industrial plants in the oil, gas, chemicals and tank terminal fields in various aspects. Core product for the process industries is the virtual plant software. It specifically addresses several pain points for companies in process industries like chemical, oil, gas, and tank terminals:

The software allows the optimisation of operational efficiency through digital twin technology, leading to significant cost savings. The VP software creates detailed, dynamic digital replicas of entire plants, capturing both physical assets and operational processes. This allows for both static and real-time data monitoring, streamlining documentation processes and ensuring stakeholders have easy access to the latest information. Additionally, the VP software optimizes maintenance schedules and procedures, reducing downtime and improving operational efficiency by ensuring timely maintenance with minimal disruption. Users can access the digital twin remotely, enhancing decision-making and collaboration among stakeholders.

Secondly, the platform facilitates the transfer of knowledge from experienced employees to junior employees by visualizing complex processes and making data accessible and understandable. The software also supports virtual meetings and training through immersive environments, allowing for interactive training modules, particularly beneficial for onboarding junior operators.

Thirdly, in response to rising energy prices, partly due to geopolitical tensions, the solution aids in identifying inefficiencies and optimizing energy usage. Lastly, their technology supports companies in meeting ESG criteria by providing tools to monitor and reduce environmental impact, ensuring compliance and sustainability. Furthermore, the company is offering regular updates, performance analytics, and optimization recommendations. They assist companies in monitoring energy usage and environmental impact, helping them to identify further efficiencies and stay compliant with evolving ESG standards.

The technology leverages laser scan data to create digital models of industrial assets, which is faster, more cost-effective, and easier to maintain compared to traditional 3D CAD-based approaches. While traditional methods can take months to complete modeling for a facility and require specialized personnel, their solution achieves the same results 5-10 times faster, reducing both time and labor costs. For example, in a recent project for a chemical manufacturing facility, this German company completed laser scanning and asset tagging for a brownfield plant in 6 weeks, whereas a comparable 3D CAD-based project was estimated to take 6 months. Additionally, their solution’s implementation costs were 50% lower, providing immediate return on investment for the client. This efficiency not only accelerates deployment but also ensures scalability for multi-site operations, a challenge for many traditional tools that are resource-intensive and difficult to maintain. Their approach enables real-time data integration and easier updates, supporting long-term operational efficiency and sustainability.

The company seeks potential users, collaborators, and partners within process industries, including oil, gas, chemicals, tank terminals, and other industrial facilities under a commercial agreement with technical assistance or an investment agreement to further develop the technology. Ideally, partners should operate one or more plants and be actively interested in improving the operational and cost efficiency of their plants. - Advantages and Innovations

-

• 5-10 times faster and up to 50% lower costs compared to trafitional 3D CAD-based solutions

• Scalability for multi-site operation

• Enhanced efficiency, safety, and profitability of plants

• Contribution to digital transformation in the industrial sector through digital twin technology

• Optimization of maintenance schedules and procedures

• Reduction of downtime

• Improved operational efficiency

• Easy onboarding of new employees/junior operators - Stage of Development

- Already on the market

- Sustainable Development Goals

- Goal 9: Industry, Innovation and Infrastructure

- Goal 13: Climate Action

- IPR status

- Secret know-how

Partner Sought

- Expected Role of a Partner

- The company is looking for potential users, collaborators, and partners active in process industries such as oil, gas, chemicals, tank terminals, and other industrial plants. The partner should ideally be operating one or several plants in such industries and be actively interested in improving the operational and cost efficiency of their plants.

- Type and Size of Partner

- SME 11-49

- SME 50 - 249

- Big company

- Type of partnership

- Commercial agreement with technical assistance

- Investment agreement

Dissemination

- Technology keywords

- 01003025 - Internet of Things

- 01003018 - User Interfaces, Usability

- 02003002 - Manufacturing plants networks

- 02004 - Plant Design and Maintenance

- 02003005 - Information processing & Systems, Workflow

- Market keywords

- 06001006 - Chemicals and materials

- 06001005 - Storage and transportation

- 06001002 - Production services

- 06002001 - Oil, gas and coal

- 08001017 - Industrial chemicals

- Sector Groups Involved

- Digital

- Energy-Intensive Industries

- Targeted countries

- All countries