Summary

- Closed for EoI

- Profile Type

- Technology offer

- POD Reference

- TODE20231018013

- Term of Validity

- 19 October 2023 - 18 October 2025

- Company's Country

- Germany

- Type of partnership

- Investment agreement

- Targeted Countries

- All countries

Contact the EEN partner nearest to you for more information.

Find my local partner

General information

- Short Summary

- A German university has improved the injection nozzle for isotropic 3D printing. The researchers have optimized the geometry of the nozzle and added a guide unit. This improves print quality and increases user flexibility. The university is offering a licensing agreement to interested companies.

- Full Description

-

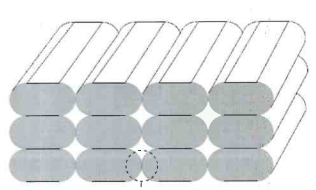

Specifically printed connecting surfaces allow optimized cohesion for individual strands during additive material extrusion processes (fused deposition modeling, or FDM; fused filament fabrication, FFF; etc.), producing better-performing structures and components that are less anisotropic.

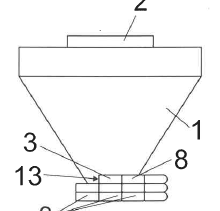

Conventional nozzles with their round outlets and flat surfaces tend to produce oval strand cross-sections, which cause gaps in the structure and generate significant anisotropic component properties. Researchers of a German university added an outlet opening to the nozzle. This can give the deformable strand (of polymer melt, for instance) any shape so that gapless connecting surfaces can be created in both horizontal and vertical orientations.

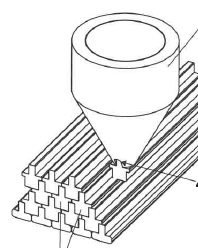

In addition to optimized geometry for changing vertical connection, a guide unit has been added to the system that presses the freshly extruded material onto the material next to or below it. This almost completely eliminates gaps between individual strands. The principle also allows printing with alternating layers (see Figure 3).

Some of the new nozzle geometries can be retrofitted to all existing FDM/FFF printers, providing a simple, low-cost option for enhancing printed material stability in all layer orientations without post-processing (warming, etc.).

The university offers a license agreement to companies, especially in the plastic industry, the automotive and aerospace sector as well as 3D printing services. - Advantages and Innovations

-

- More isotropic component properties from conventional extrusion printing

- Combines pressure and printing

- Can be retrofitted modularly

- Improved product properties

- Increased transparency

- Individually adaptable nozzle systems

- Near-to-net shaping

- Alternating layers - Stage of Development

- Lab tested

- Sustainable Development Goals

- Goal 9: Industry, Innovation and Infrastructure

- IPR status

- IPR applied but not yet granted

- IPR notes

- The university submitted a German patent application for the invention with the option of international expansion in May 2023.

Partner Sought

- Expected Role of a Partner

- The university offers a license agreement to companies, especially in the plastic industry, the automotive and aerospace sector as well as 3D printing services.

- Type and Size of Partner

- Other

- SME 11-49

- Big company

- SME <=10

- SME 50 - 249

- Type of partnership

- Investment agreement

Dissemination

- Technology keywords

- 02007014 - Plastics, Polymers

- Market keywords

- 08001001 - Plastic fabricators

- 08001006 - Processes for working with plastics

- Targeted countries

- All countries