Summary

- Profile Type

- Technology offer

- POD Reference

- TODE20231018009

- Term of Validity

- 18 October 2023 - 17 October 2025

- Company's Country

- Germany

- Type of partnership

- Investment agreement

- Targeted Countries

- All countries

Contact the EEN partner nearest to you for more information.

Find my local partner

General information

- Short Summary

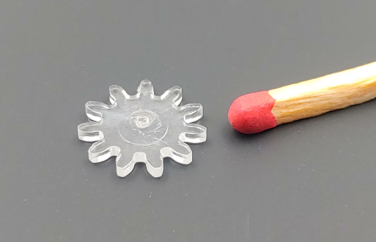

- A German university has developed an economic micro-component injection molding process for all batch sizes. The injection molding unit concept allows greatly reduced dwell times, low energy consumption, and very good reproducibility. The university offers a lisence agreement.

- Full Description

-

Economic micro-component injection molding (for all batch sizes) is no longer a pipe dream. A German university Köln has developed a polymer laboratory in which it has discovered how to economically melt and inject thermoplastics not only in multiple cavities, but also with single-cavity molds. The injection molding unit concept allows greatly reduced dwell times, low energy consumption, and very good reproducibility.

This is accomplished with a new type of shut-off needle integration into the injection piston and clever plastic melt guidance. Injection unit volume is so low that short dwell times can be achieved in single-cavity molds even without oversized gating systems. The unit can be combined with sprueless injection molds. Dwell time was reduced by more than 90%. Material flow is FIFO (First In – First Out).

The university offers a licensing agreement to companies in the plastics industry. - Advantages and Innovations

-

The main advantages of this invention are:

- Competitive Advantages

- Short dwell time

- Energy-saving potential

- Increased, reproducible precision

- Can be sprueless - Stage of Development

- Lab tested

- Sustainable Development Goals

- Goal 9: Industry, Innovation and Infrastructure

- IPR status

- IPR applied but not yet granted

- IPR notes

-

The university has submitted a German patent application for the invention with the option of international

expansion.

Partner Sought

- Expected Role of a Partner

- The university offers a licensing agreement to companies in the plastics industry.

- Type and Size of Partner

- SME 50 - 249

- Big company

- Other

- SME 11-49

- SME <=10

- Type of partnership

- Investment agreement

Dissemination

- Technology keywords

- 002002013 - Moulding, injection moulding, extrusion, sintering

- 02007014 - Plastics, Polymers

- Market keywords

- 08001001 - Plastic fabricators

- Targeted countries

- All countries