Summary

- Profile Type

- Business Offer

- POD Reference

- BOIT20231215017

- Term of Validity

- 19 December 2023 - 18 December 2025

- Company's Country

- Italy

- Type of partnership

- Commercial agreement

- Supplier agreement

- Targeted Countries

- All countries

Contact the EEN partner nearest to you for more information.

Find my local partner

General information

- Short Summary

-

An Italian SME based in Northern-Italy and founded in 1986 has strong expertise in the manufacturing of thermosetting polymer articles, especially rubber and silicon technical products.

The SME is seeking partnerships mainly targeting the following industries: oil & gas, food machinery, military, naval, automotive, aerospace, construction, installations for multi-utility, fire protection, renewable energy, electrical connectors, equipments / tools / valves for water installations. - Full Description

-

Since 1986 the SME is a manufacturer of thermosetting polymer articles, especially rubber and silicon technical products.

It can produce customized articles, fairleads, frames, lip seals, membranes, o-rings, pads, suckers for different applications, washers.

Application area range from sanitary fittings, electric households, pneumatic systems, food stuffs, automotive, medical and gas/air flow control, food machinery, hydraulic, pneumatics, water pipeline, oil & gas valves.

Customized products are studied together with the customer: from conception to the selection of material, to the choice of production process. The birth of the article is constantly monitored and controlled.

The SME can also offers:

- consultancy in the selection of the best material to achieve the objective;

- for rubber articles, the combination compounds and in-house production of compounds;

- the possible creation of new formulas for the sought materials;

- the choice of the most suitable production process;

- the possible prototyping of an innovative product on which to perform quality tests;

- accurate manufacturing production planning and monitoring of each step;

- eventually, the project of the mould - the eventual realization of the mould, if necessary, in partnership with the best mould workshops in Sebino Rubber District;

- any support in the choice and management of the relationship with the company in charge of mould construction;

- constant research, also in collaboration with universities and research centres, for the sustainability of partners'/customers' products;

- training for partners/customers;

- absolute restraint.

The company conducts the full production process internally.

The SME's research lab recommends the best materials and equipment for the given project.

Using 2D and 3D software, the designs are reviewed. Then, in collaboration with the client, the final details are defined, the best combination is selected, and the production process is established.

The company works with more than 550 compounds, spanning 11 families of thermoset polymers. 35 of these have been fully developed by the SME.

Tests conducted in-house in the laboratory guarantee that every single part meets the dimensions specified in the drawing.

The company is already successful in both domestic and foreign markets. Over the years, it has produced more than 3.000 bespoke items and develops more of a partnership relationship with its clients than a supply-only one.

The SME is seeking new partners worldwide – mainly in USA, India, Europe, Russian Federation, but not only - in order to expand its business, with the goal of establishing long-term business relationships.

Potential partners can be:

- entrepreneurial partners with whom to realize new products;

- companies interested in having their own range of suction cups for their own internal use or for their customers;

- new business relationship especially targeting the following industries: oil & gas, food machinery, military, naval, automotive, aerospace, construction, installations for multi-utility, fire protection, renewable energy, electrical connectors, equipments / tools /valves for water installations;

- new business relationship into the fashion and gadget world;

- companies interested in having their own range of replacement items for their own internal use or for their customers;

- organizations interesting in developing increasingly environmentally friendly thermosetting polymer types. - Advantages and Innovations

-

The advantages of the company include:

- the flexibility, the extreme precision, and the infinite care about customer's needs. This is why 80 % of the SME’s projects are multi-year: because clients rely on consistent quality and service;

- the Research and Development laboratory, equipped with the best last generation technology, provides a constant supervision both on the raw materials, and during the manufacturing process. Moreover, thanks to the management software developed by the company, 100% of production is always traceable, with 24-hour monitoring of 100% of the production. It is possible to track the entire production process and analyze any issues that are identified and linked to the product;

- international approach;

- continuous investment in the production process;

- the SME, which is already ISO 9001 and IATF 16949 certified, is working on a daily basis towards further, different certifications in accordance with customer requirements;

- moreover, the company has started three sustainability projects in order to also be able to produce components that reduce the environmental impact of customers' products. - Stage of Development

- Already on the market

- Sustainable Development Goals

- Goal 9: Industry, Innovation and Infrastructure

- Goal 12: Responsible Consumption and Production

Partner Sought

- Expected Role of a Partner

-

The company is looking for partners in order to expand its business in foreign markets, mainly in USA, India, Europe, Russian Federation, but not only.

Potential partners can be:

- entrepreneurial partner interested in developing new products containing thermosetting and polymers;

- entrepreneurial partner or research organization interested in making thermoset polymers with less environmental impact;

- customers interested in being supplied by this SME;

- companies interested in having their own range of suction cups for their own internal use or for their customers;

Cooperation is envisaged under a commercial or supplier agreement.

Further details shall be discussed directly with potential partners. - Type and Size of Partner

- SME 50 - 249

- SME 11-49

- Other

- R&D Institution

- Big company

- University

- SME <=10

- Type of partnership

- Commercial agreement

- Supplier agreement

Dissemination

- Technology keywords

- 02007010 - Metals and Alloys

- Market keywords

- 08001012 - Speciality metals (including processes for working with metals)

- Sector Groups Involved

- Energy-Intensive Industries

- Renewable Energy

- Mobility - Transport - Automotive

- Targeted countries

- All countries

Images

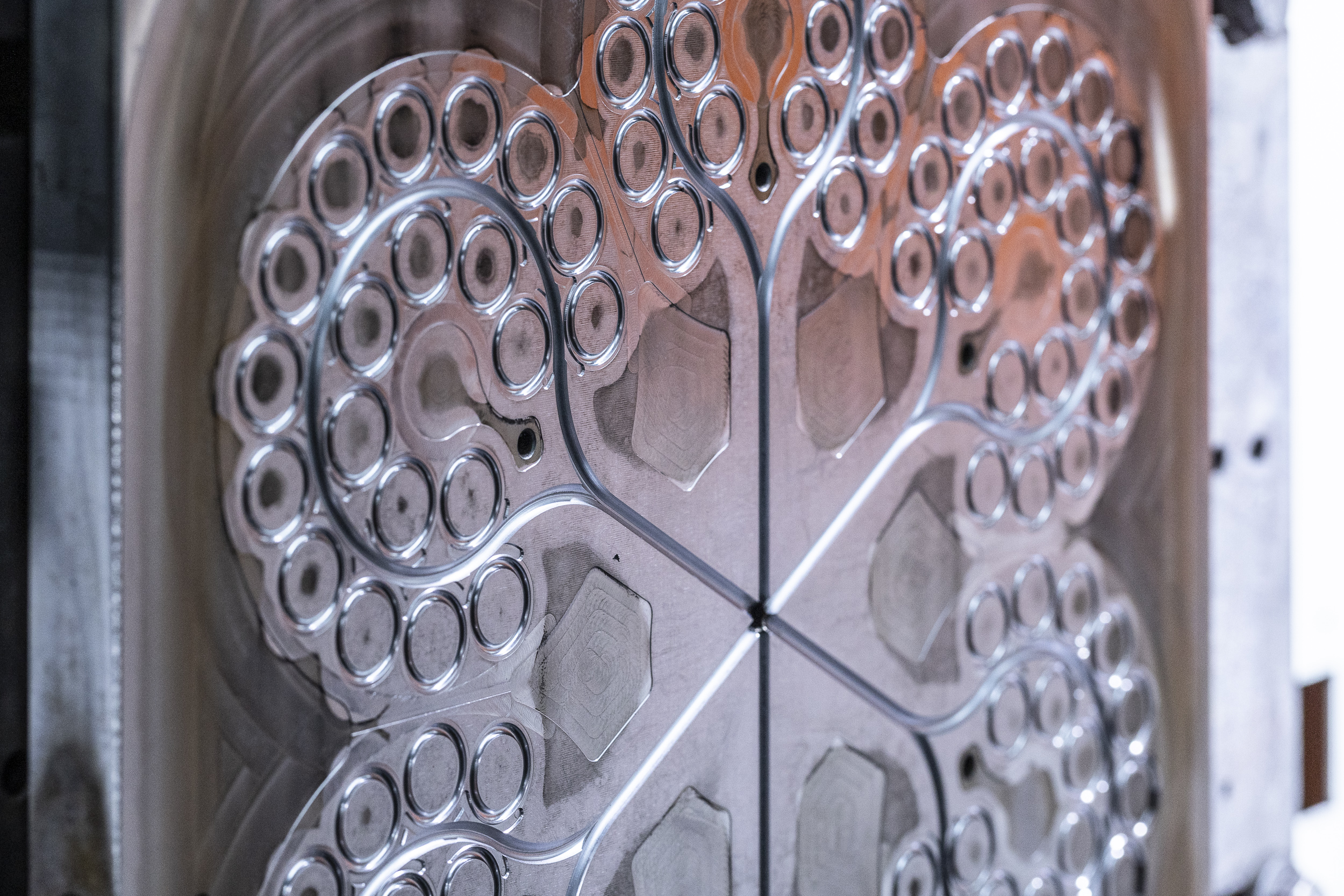

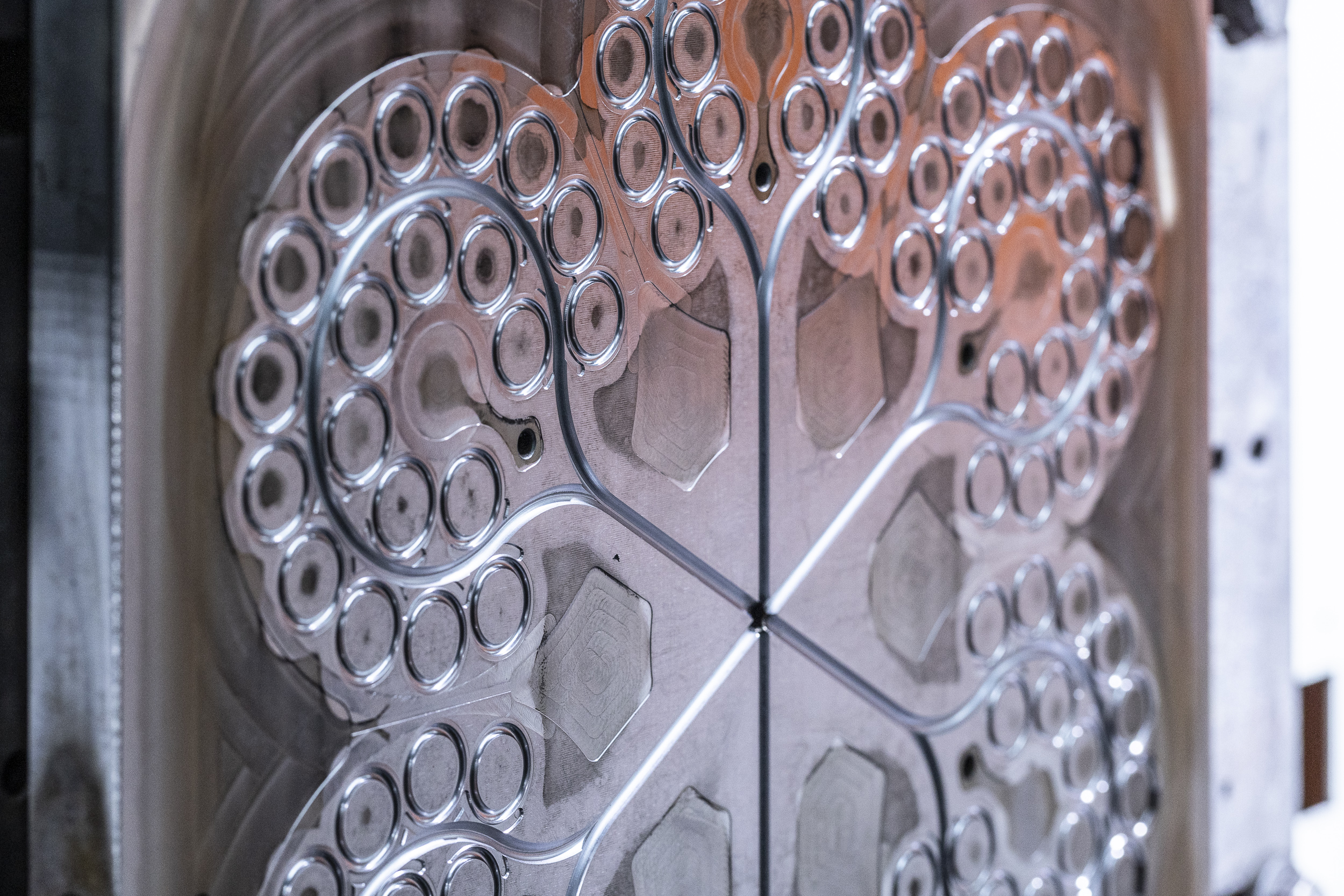

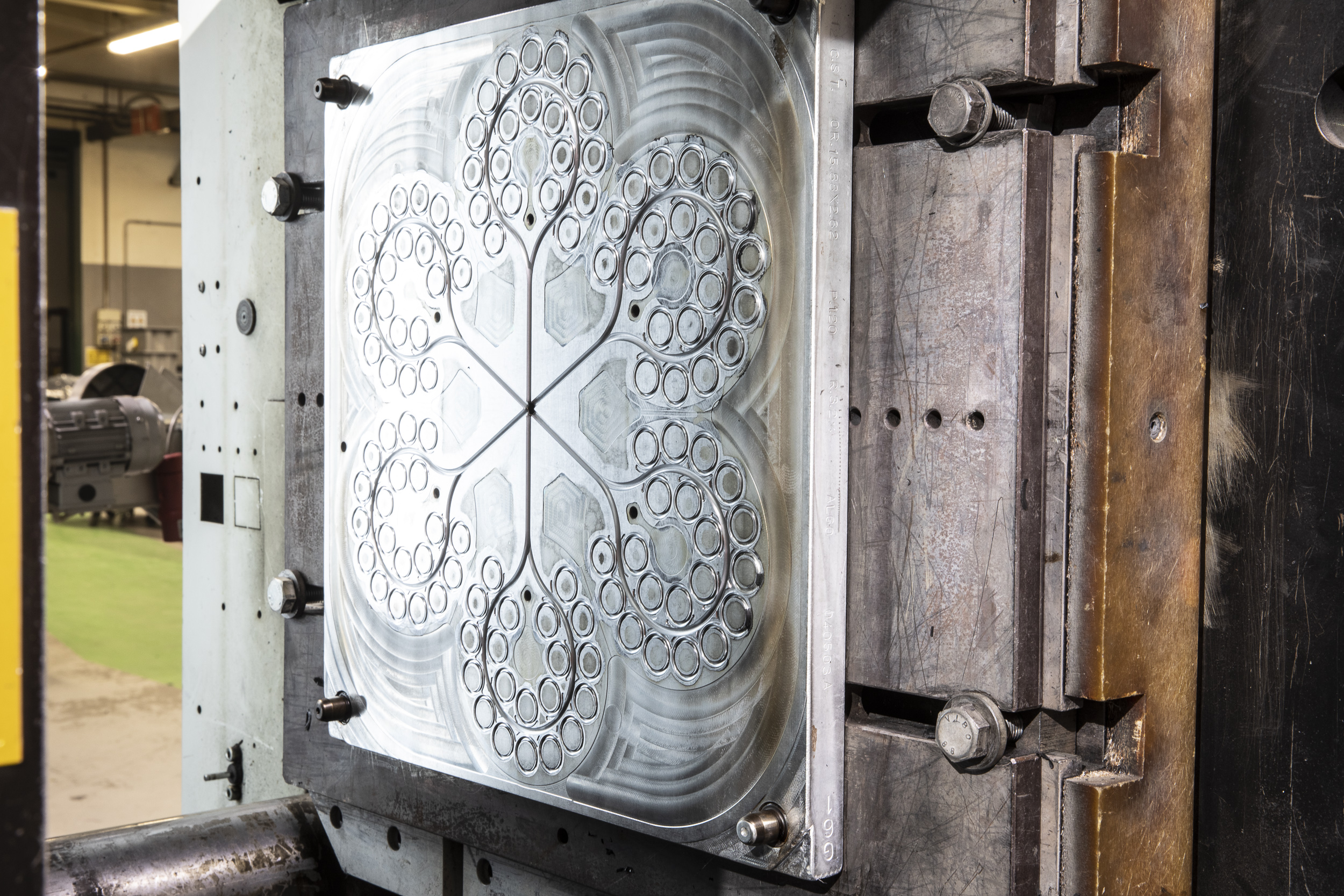

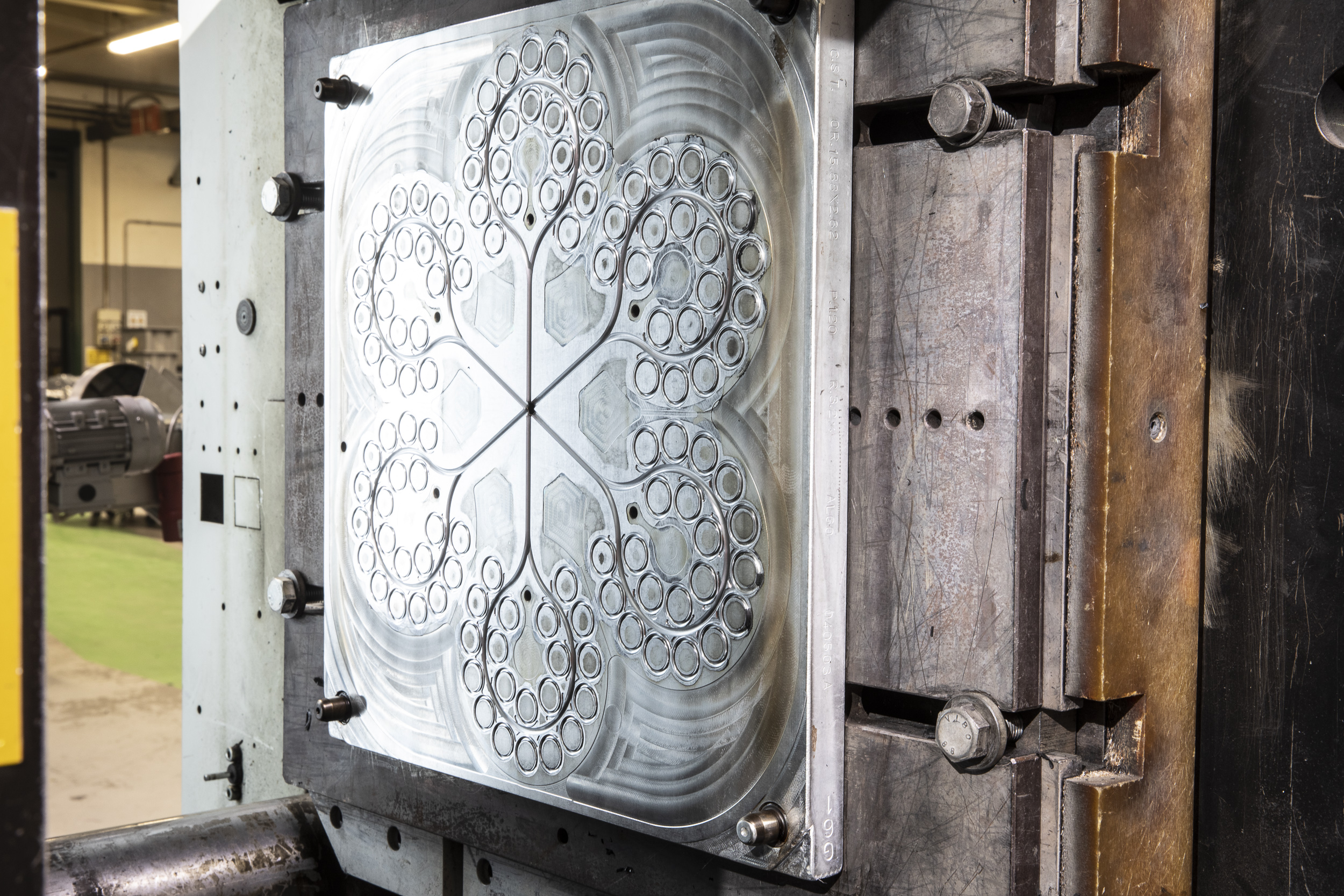

Detail of a mould

Raw material control instrument (TGA e DSC)

A productive machine

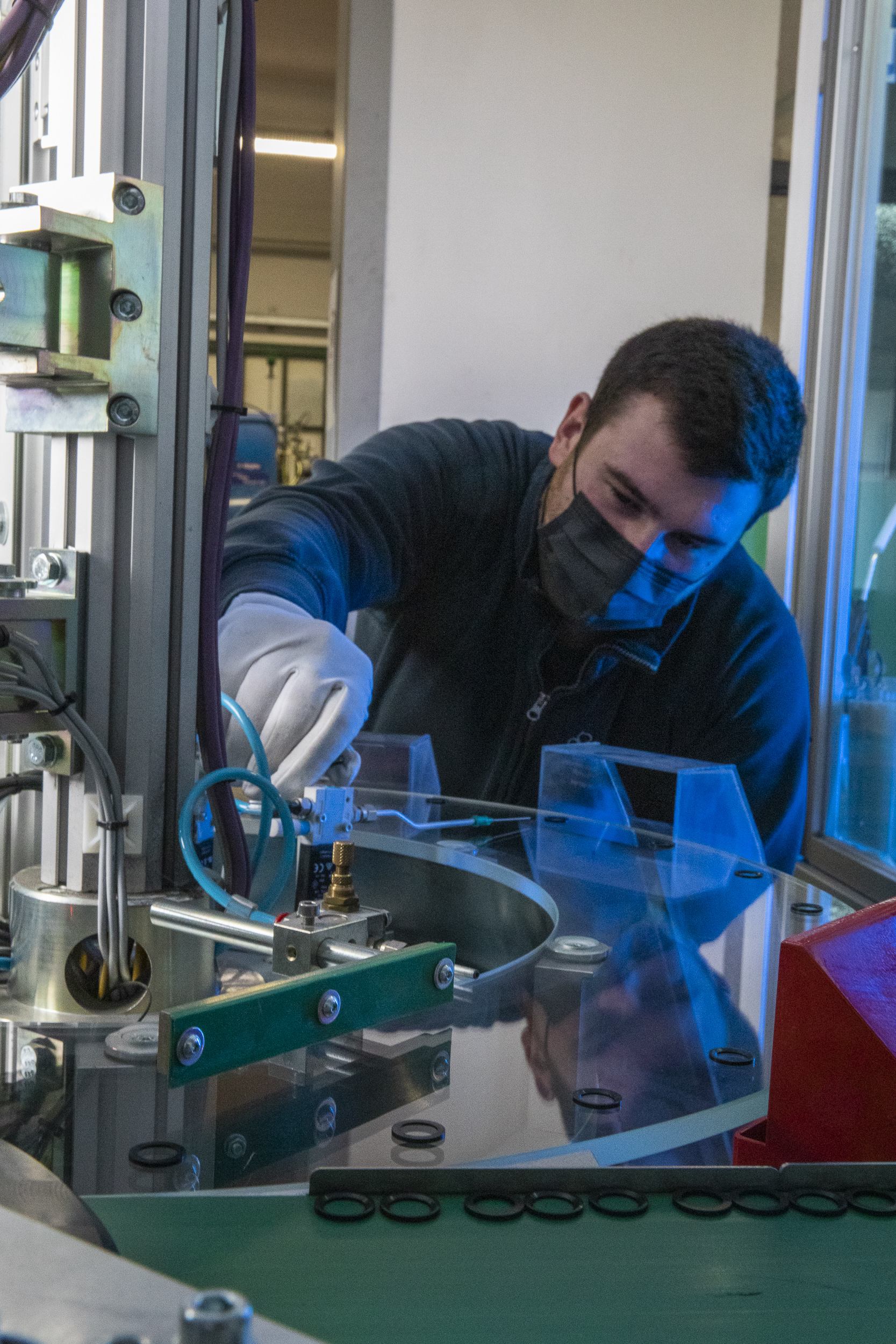

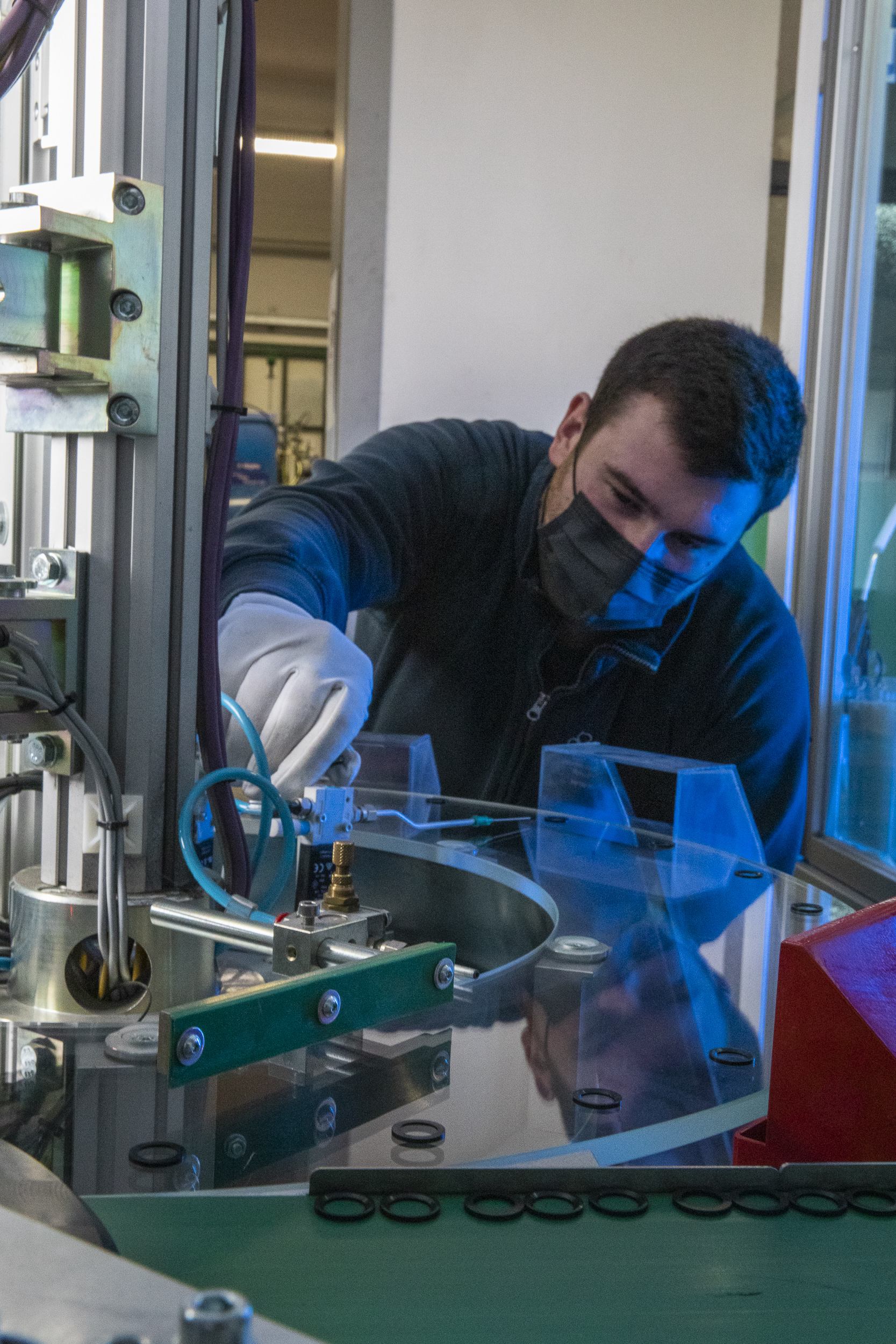

Close-up view of a productive machine

Activity of the mould workshop

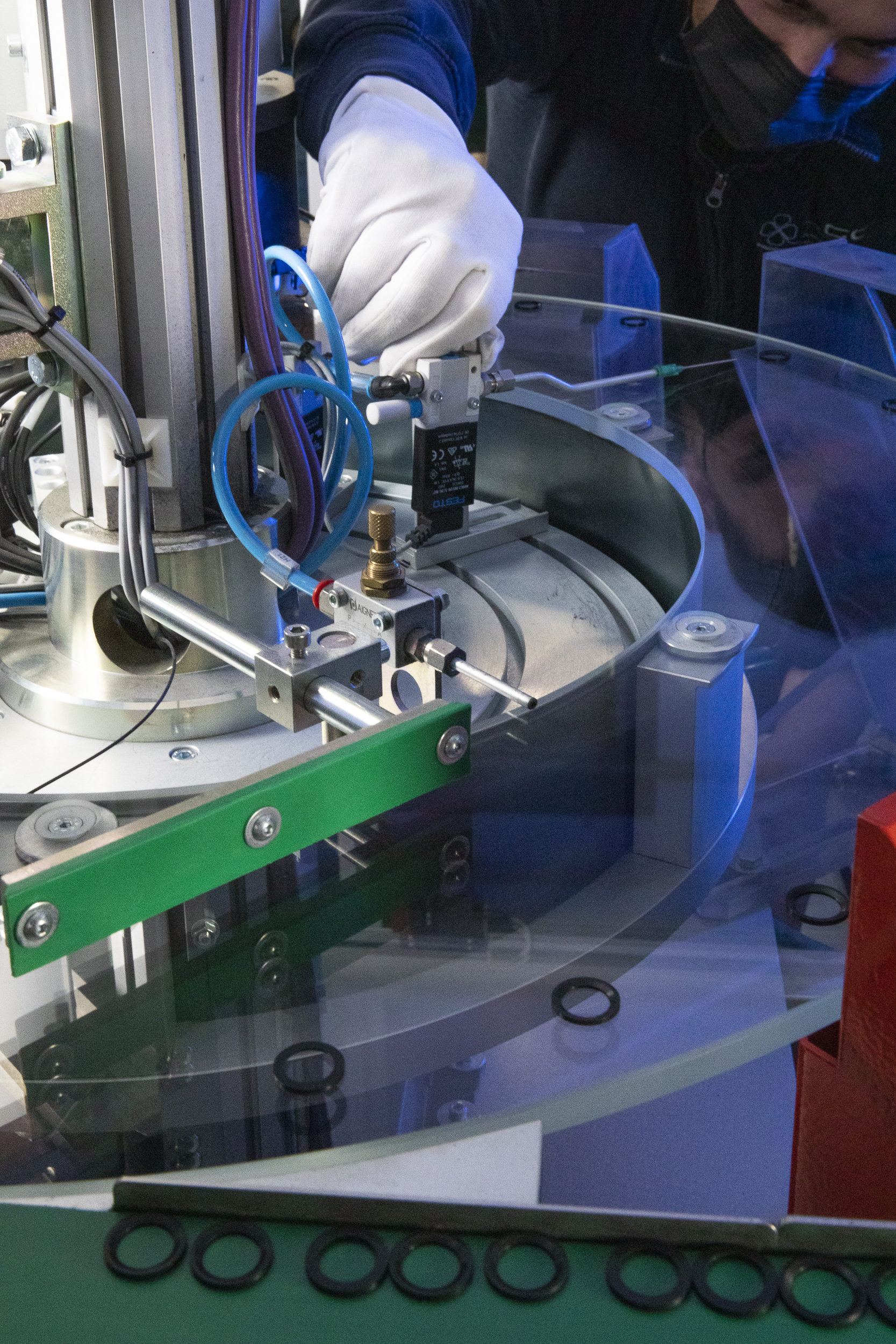

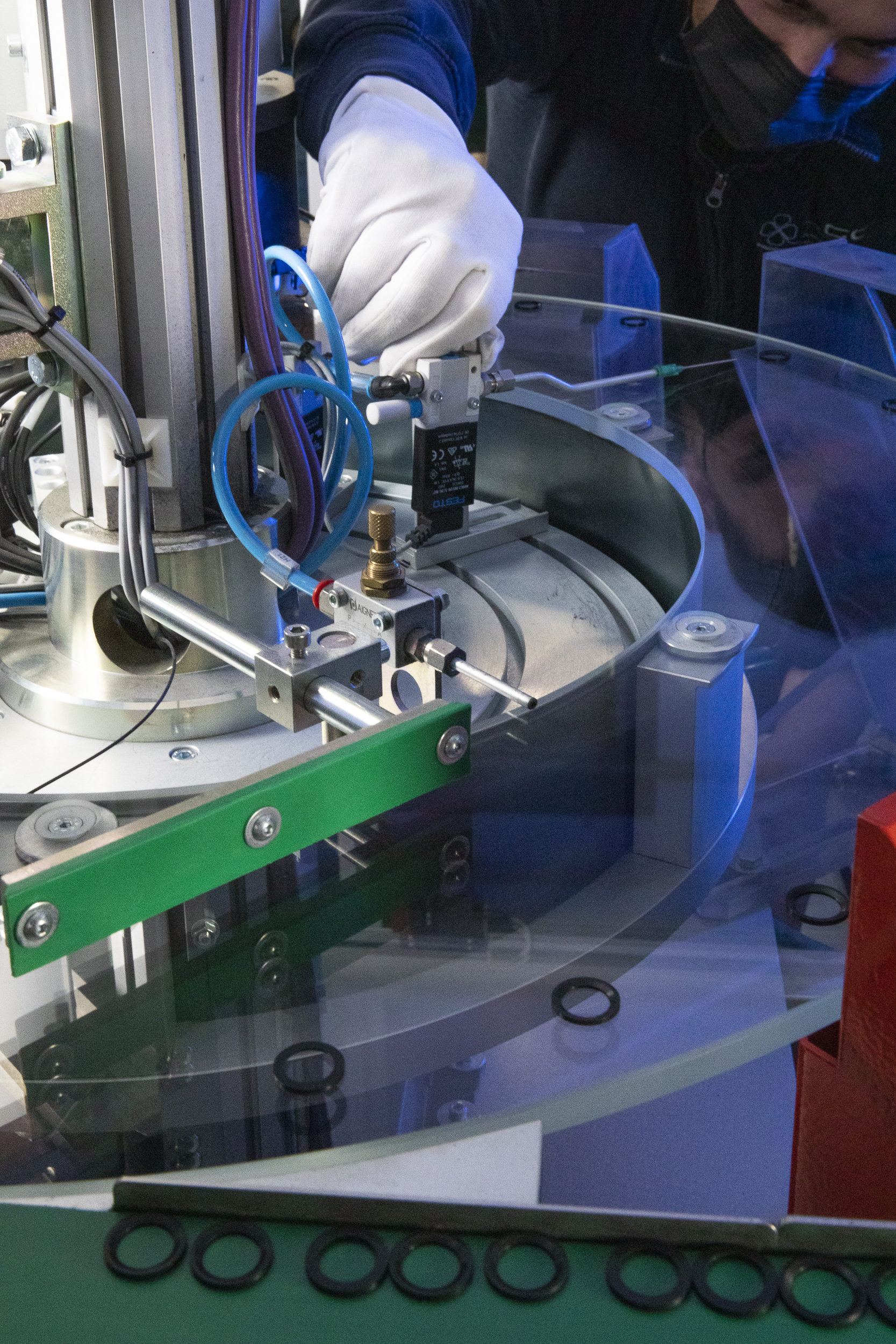

Detail of a productive machine

Other productive machine

Close up view of another productive machine

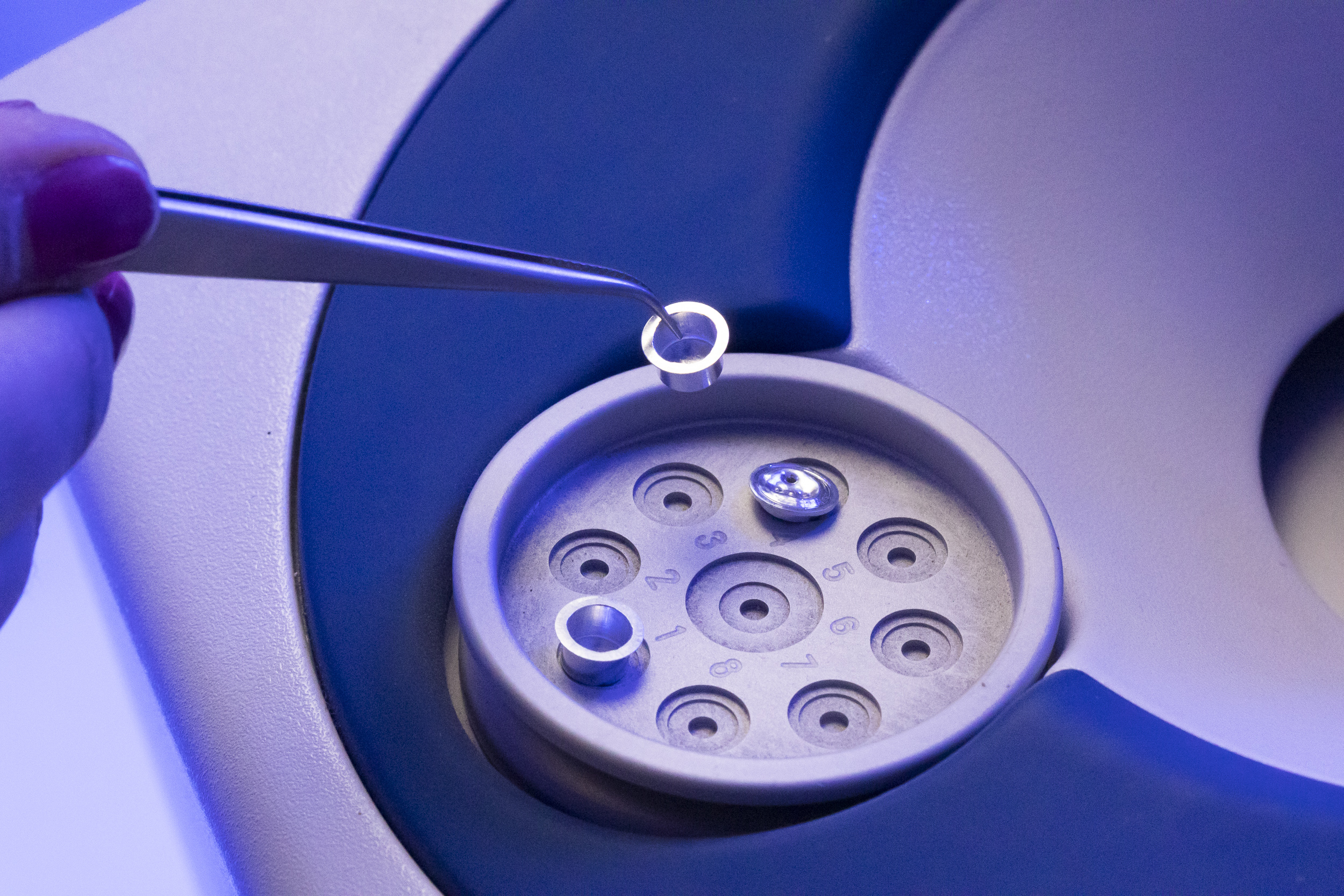

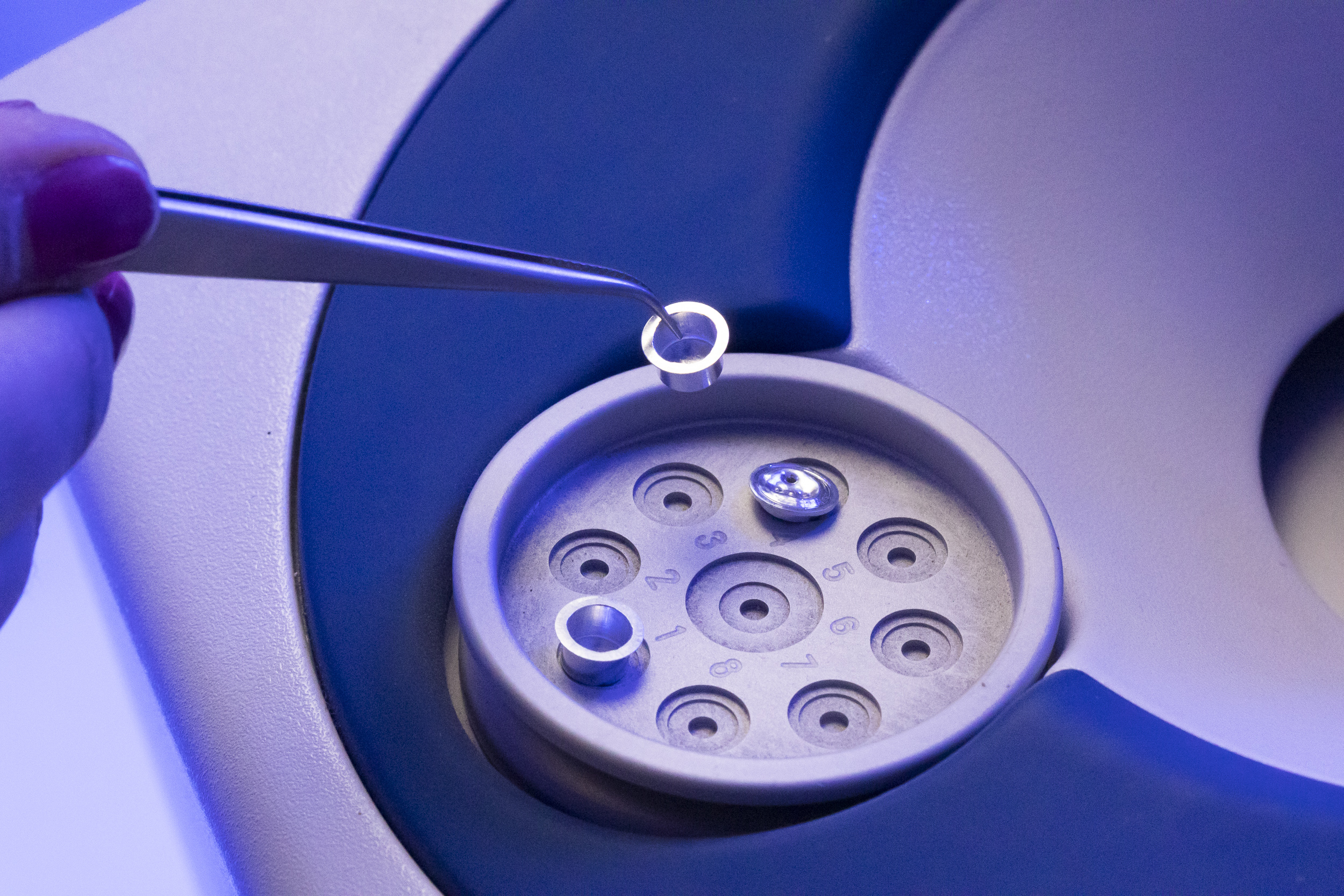

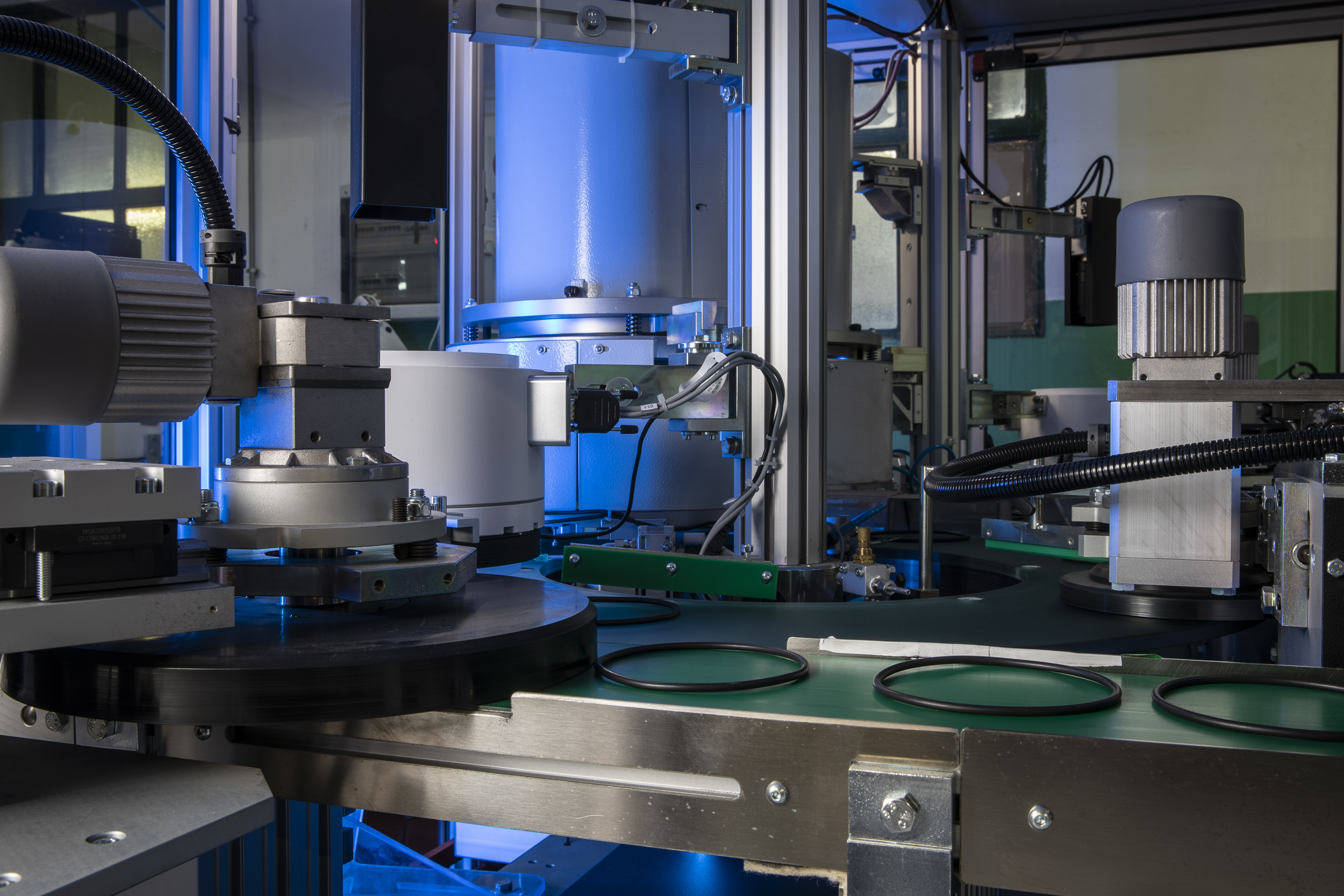

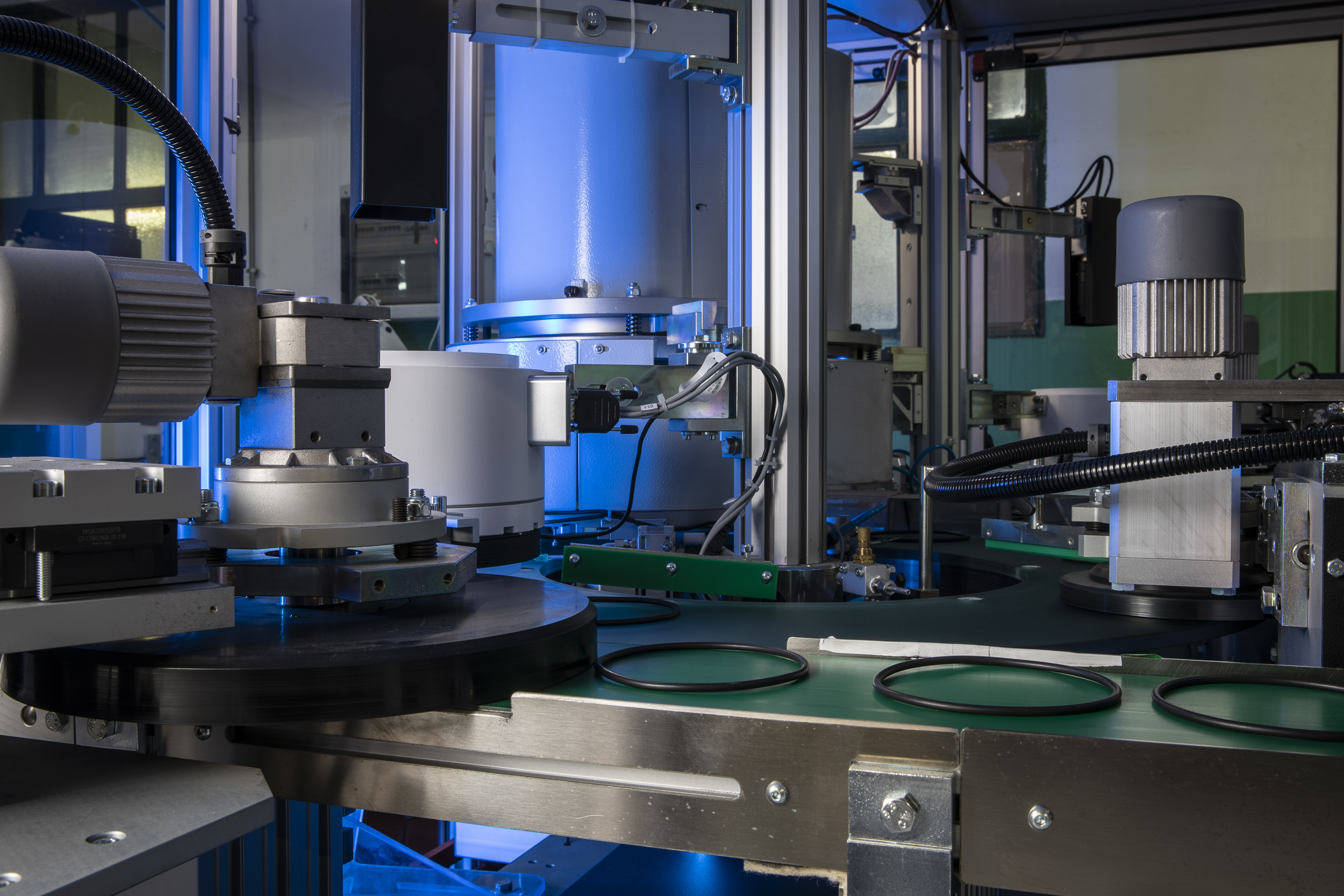

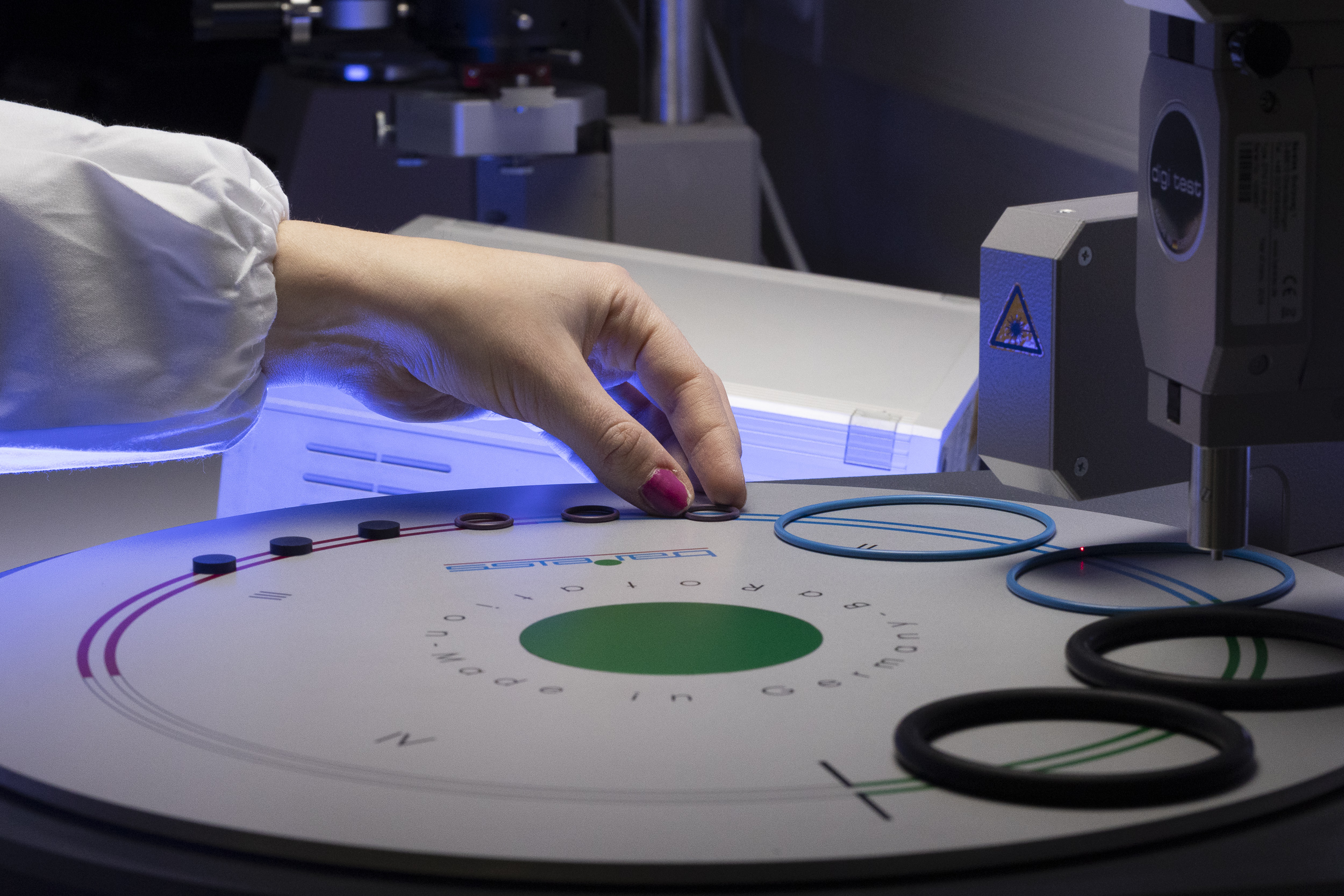

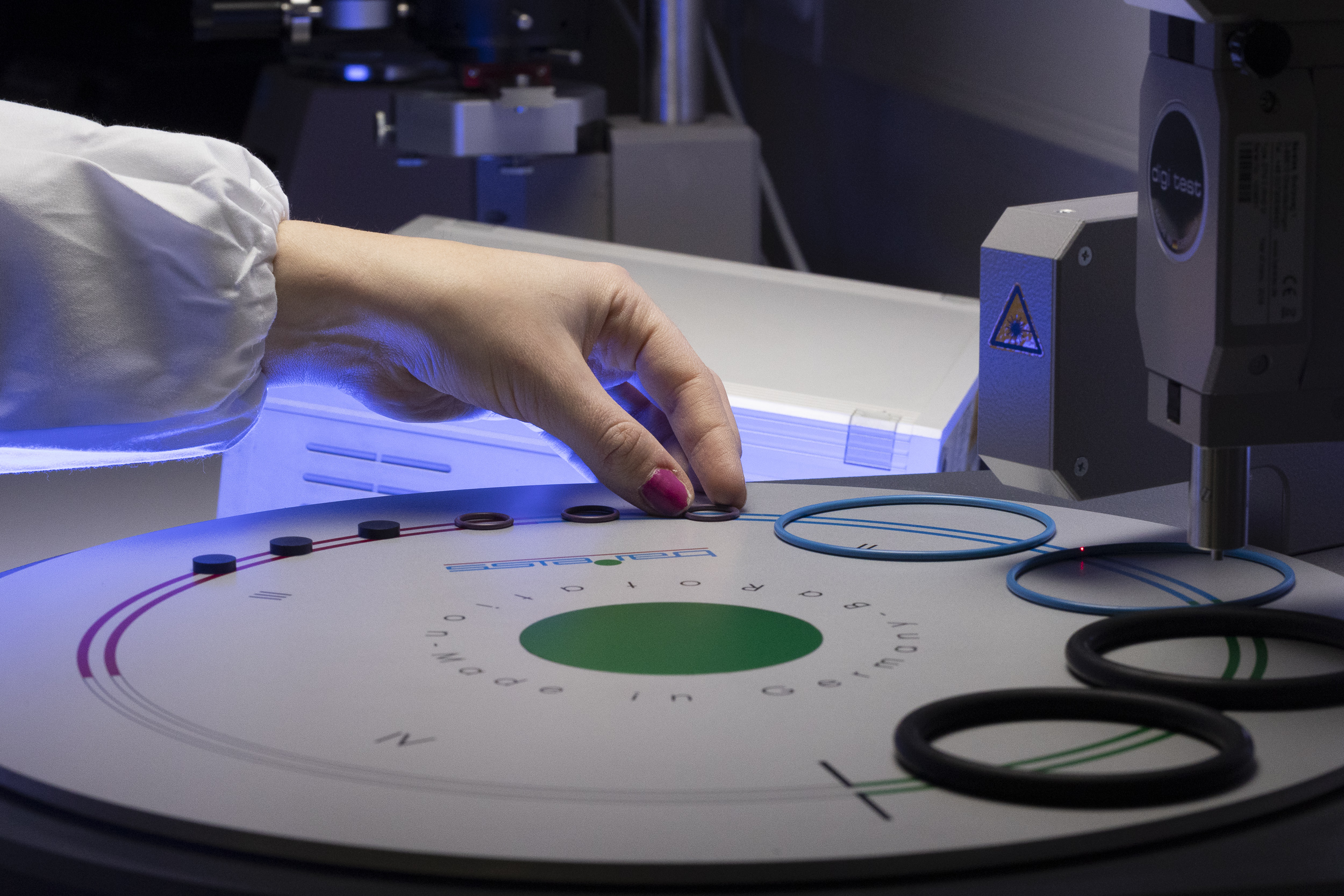

One-step quality control for 100 per cent of the parts

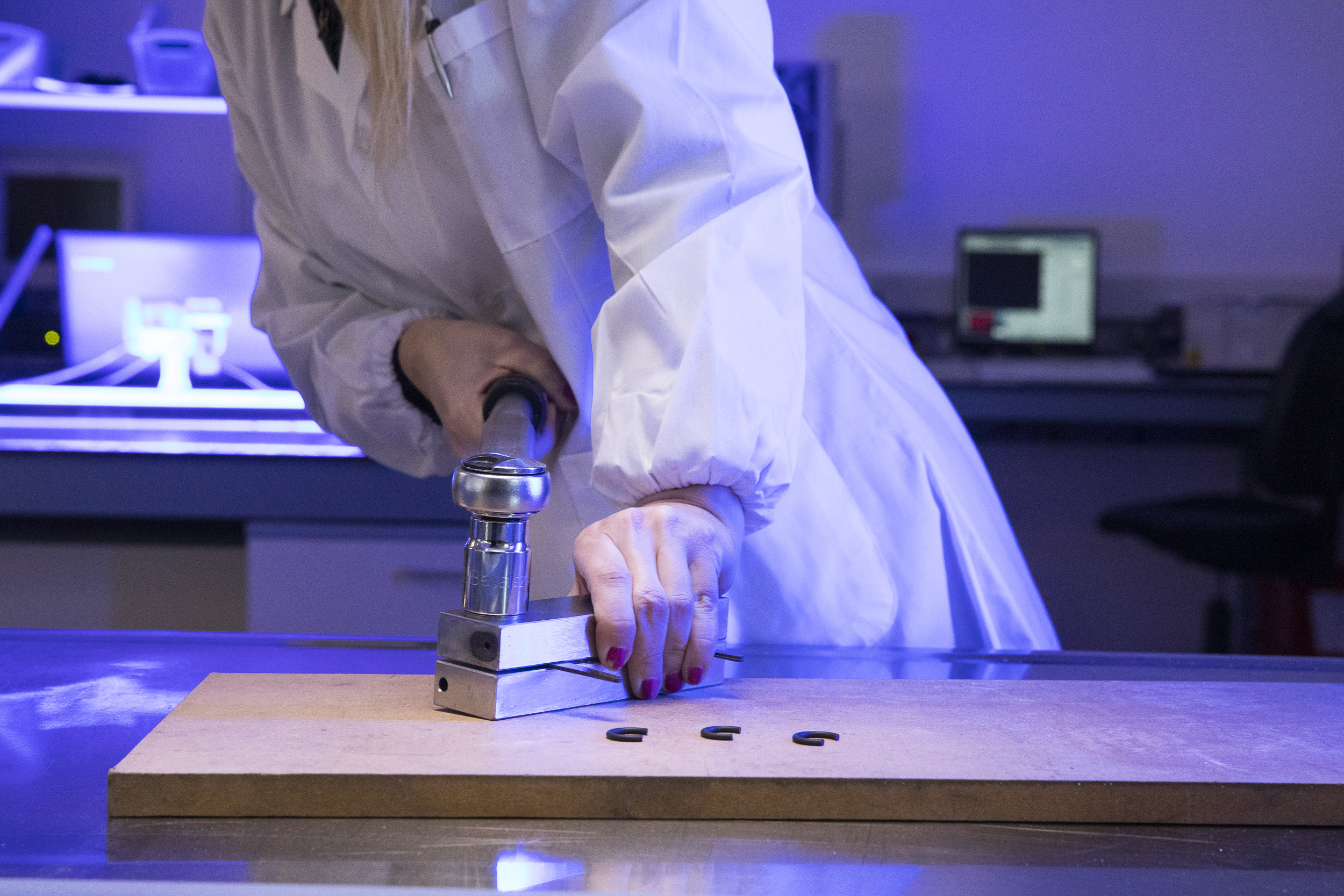

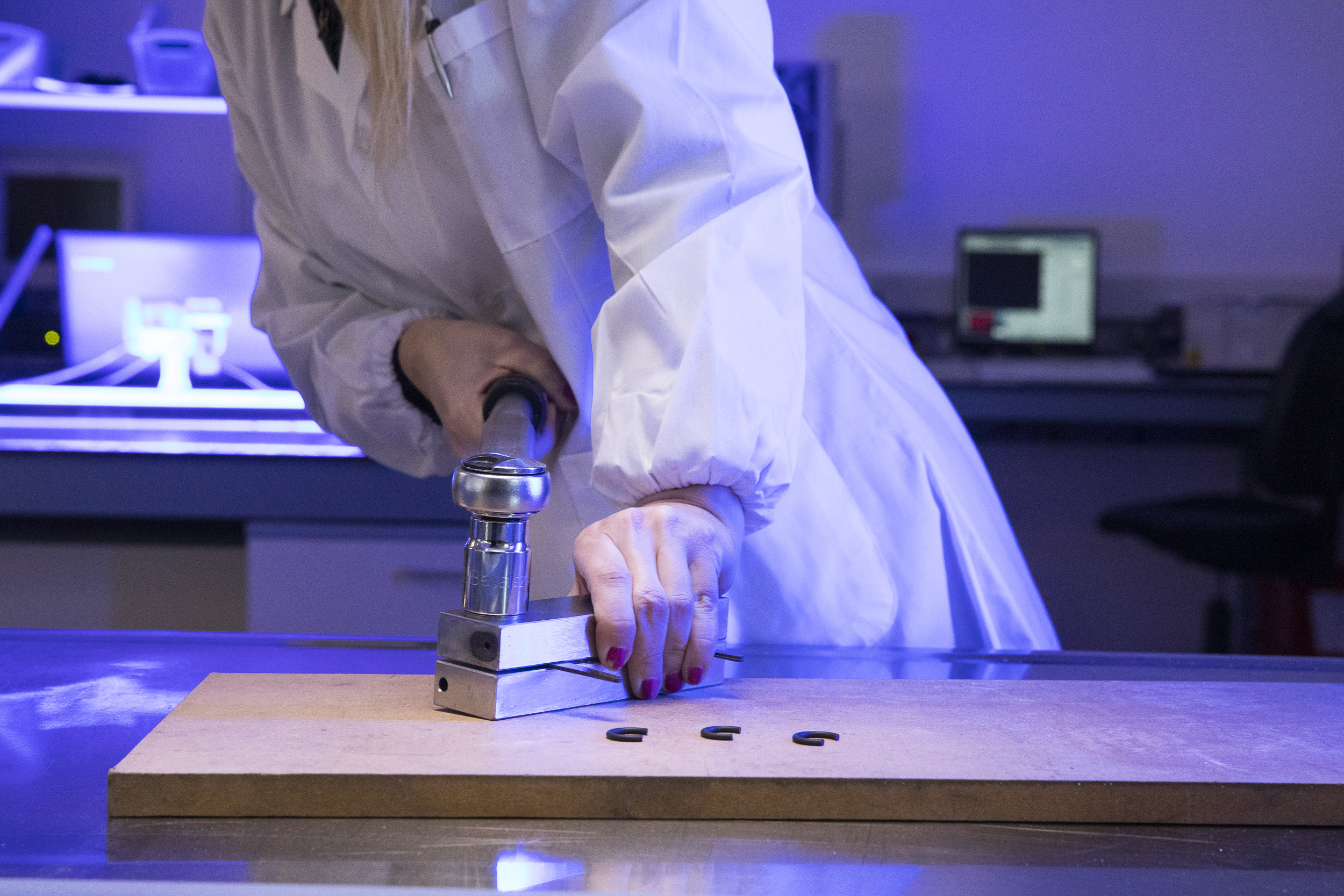

Quality control phase

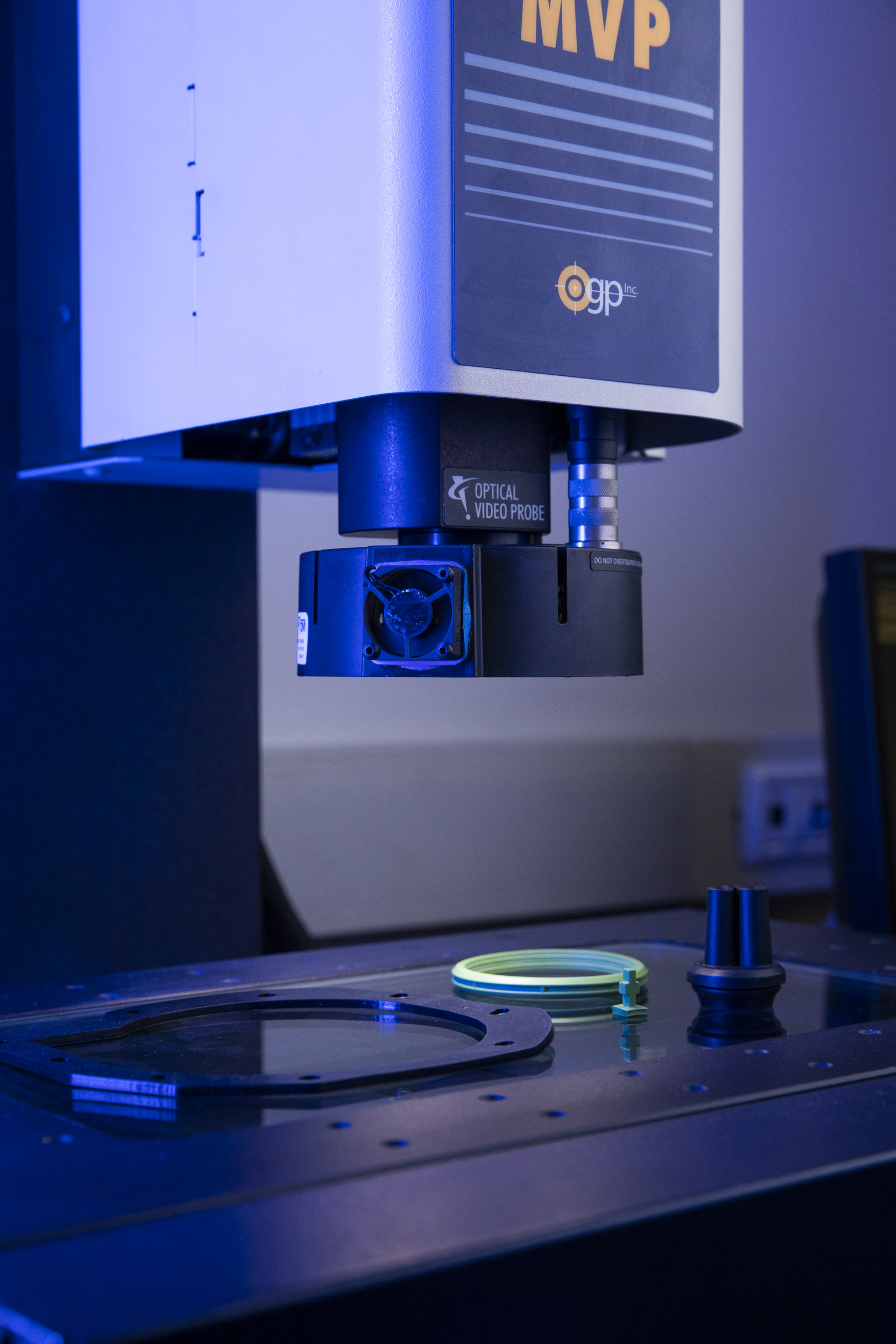

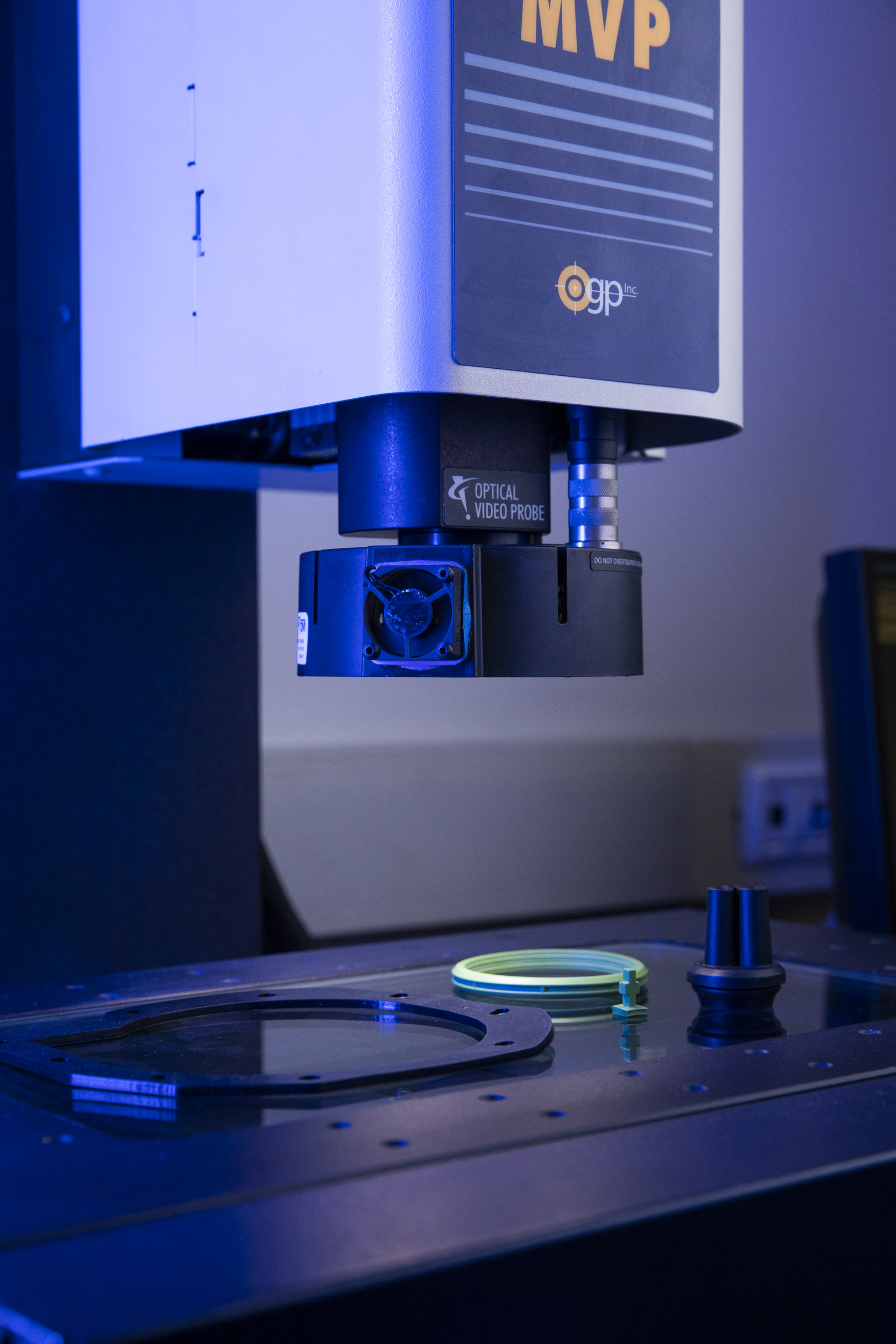

OGP viewer for quality control

Automatic hardnesss testing

Example of a mould

Detail of the automatic hardness testing

Laboratory

Laboratory analyses

Thickness gauge test

Analyses with durometer

Compression set test