Summary

- Profile Type

- Business Offer

- POD Reference

- BOIT20231120001

- Term of Validity

- 27 November 2023 - 26 November 2025

- Company's Country

- Italy

- Type of partnership

- Commercial agreement

- Targeted Countries

- All countries

Contact the EEN partner nearest to you for more information.

Find my local partner

General information

- Short Summary

- An Italian SME based in Northern-Italy and founded in 1968 specialized in aluminium and zamak die casting processes is seeking long-term partnerships in different fields such as agriculture, hydraulics, industrial automation, professional appliances, measuring instruments, hydraulics, tools, home automation, industrial cleaning machinery, surveillance systems.

- Full Description

-

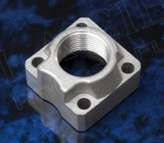

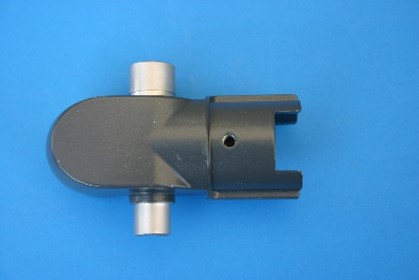

Founded in 1968 and based in Lombardy, this Italian SME is currently in its third generation of family ownership. It specializes in pressure die-casting with inserts, zamak and aluminium in various alloys, with weights ranging from 10 grams to 5 kilograms, using computerized horizontal cold chamber presses with capacities ranging from 150 tons to 650 tons.

With a focus on the following market sectors, the SME has developed a strong understanding of die-casting processes: hydraulics, electrical, electronics, oil and gas, agriculture, pneumatics, industrial automation, cleaning machines, professional appliances, measuring instruments.

The SME can provide a whole range of services, from co-designing the mould with the client to actually realizing the die-casted parts in all their finishing. To avoid issues with the mechanical workings, it relies on an X-ray machine equipped with tomography to find the porosities and a 30-kilometer network of partners for the finishing operations.

The distinctive features of the SME are:

- its work ethic based on the principle of working closely with the final customer utilizing a co-design approach;

- it can offer small-to-medium-sized die-casting batches (minimum 1.000 pieces) at regular prices and delivery times;

- it can supply die-castings aluminum and zinc alloy products including steel or brass inserts during the melting process;

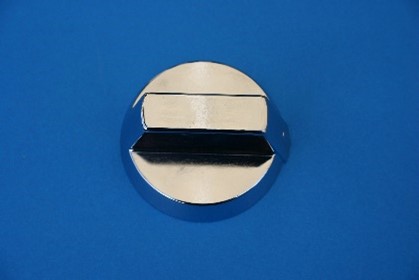

- to obtain finished products, it carries out intricate machining as well as surface and protection treatments: blanking, deburring, surface and protective treatments (sandblasting, tumbling, polishing, painting and nickel & chromium plating) machining (from simple threads to most complex mechanical working) and customized packaging;

- usage of special alloys and a max flexibility thanks to the oven by the machines;

- only certified material with carbon footprint certificate and coming from areas where human rights are granted;

- prompt delivery fir products that are in stock, upon customer’s authorization for safety stock.

The company is already successful in both domestic and international markets. The SME is seeking for new partners worldwide to expand its business, with the goal of establishing long-term business relationships.

Potential partners can be producers of goods for different fields, such as agriculture, lighting, home appliances, cleaning machines, pneumatics, elevator pumps, thermocopies, measurement tools, components for industrial kitchens looking for the realization of die casted parts in aluminium and zamak. - Advantages and Innovations

-

The SME stands out for the consistency of its values, which include:

- keeping its employees trained and motivated;

- ensuring that the die casting production process is environmentally sustainable: the die casting process is certified in accordance with ISO 50001 standards, so ensuring the sustainability of the manufacturing process;

- in recent years, to ensure that clients receive ongoing assistance, the company has made investments in new die casting machines and connected services and new in technologies 4.0.

All the procedures involved in supporting business operations, including production planning and die casting control, logistics and inventory, sales, purchasing, general accounting and CRM, can be integrated with its ERP controlling system.

In addition to enabling the traceability of die cast batch production, the software solution provides clients with real-time information about production and order status throughout the whole manufacturing process, from die casting to shipment;

- to continuously improve, it has made targeted investments, for example a new PLC/PC system installed on each die casting machine and simulation software for filling die casting molds. These systems control and monitor all critical data related to each die cast production batch, such as second phase injection speed, multiplicated speed, and multiplicated pressure, and they ensure to customers full traceability of each mold and improved mold durability because they track key die casting parameters in real-time, particularly the second phase injection speed. The possibility to provide its clients with technical documentation for the manufacturing batches in both German and English further demonstrates its added value.

The company also focuses a lot on quality:

- it is UNI EN ISO 9001:2015 certified;

- specific quality requirements are directly discussed with customers, and relevant tests are integrated into the production process;

- it can assure real-time production and quality - Stage of Development

- Already on the market

- Sustainable Development Goals

- Goal 9: Industry, Innovation and Infrastructure

- Goal 12: Responsible Consumption and Production

- Goal 8: Decent Work and Economic Growth

- IPR status

- No IPR applied

Partner Sought

- Expected Role of a Partner

-

The company is looking for partners in order to expand its business in foreign markets.

Potential partners can be producers of goods for different sectors, such as agriculture, lighting, home appliances, cleaning machines, pneumatics, elevator pumps, thermocopies, measurement tools, components for industrial kitchens looking for reliable partners for the realization of die casted parts in aluminium and zamak.

In this case the cooperation is envisaged under a commercial agreement. Further details shall be discussed directly with potential partners. - Type and Size of Partner

- Other

- Big company

- SME 11-49

- SME 50 - 249

- SME <=10

- Type of partnership

- Commercial agreement

Dissemination

- Technology keywords

- 02007011 - Non-ferrous Metals

- 02007010 - Metals and Alloys

- Market keywords

- 08003001 - Machine tools, other metal working equipment (excl. numeric control)

- 08001012 - Speciality metals (including processes for working with metals)

- Targeted countries

- All countries