Summary

- Profile Type

- Business Offer

- POD Reference

- BOJP20240702019

- Term of Validity

- 2 July 2024 - 2 July 2026

- Company's Country

- Japan

- Type of partnership

- Commercial agreement

- Targeted Countries

- All countries

Contact the EEN partner nearest to you for more information.

Find my local partner

General information

- Short Summary

-

A Japanese manufacturer of lathe chucks and precision rotary tables for Electrical Discharge Machining (EDM) is looking for a dealer or a distributor in the EU under a commercial agreement. Ideally, the collaboration could take the form of a business alliance based on a mutually agreed contract.

The company products over perform competitors in terms of quality, allowing significant money and time savings. - Full Description

-

The Japanese company has been engaged in manufacturing and sales of machine tool peripheral equipment for over 70 years. They provide a wide variety of high-quality customised solutions and services, mainly for lathe chucks and Electrical Discharge Machining machinery, to meet the specific requirements and needs of their customers, both domestic and international. They are also striving to make quality products that would last for many years.

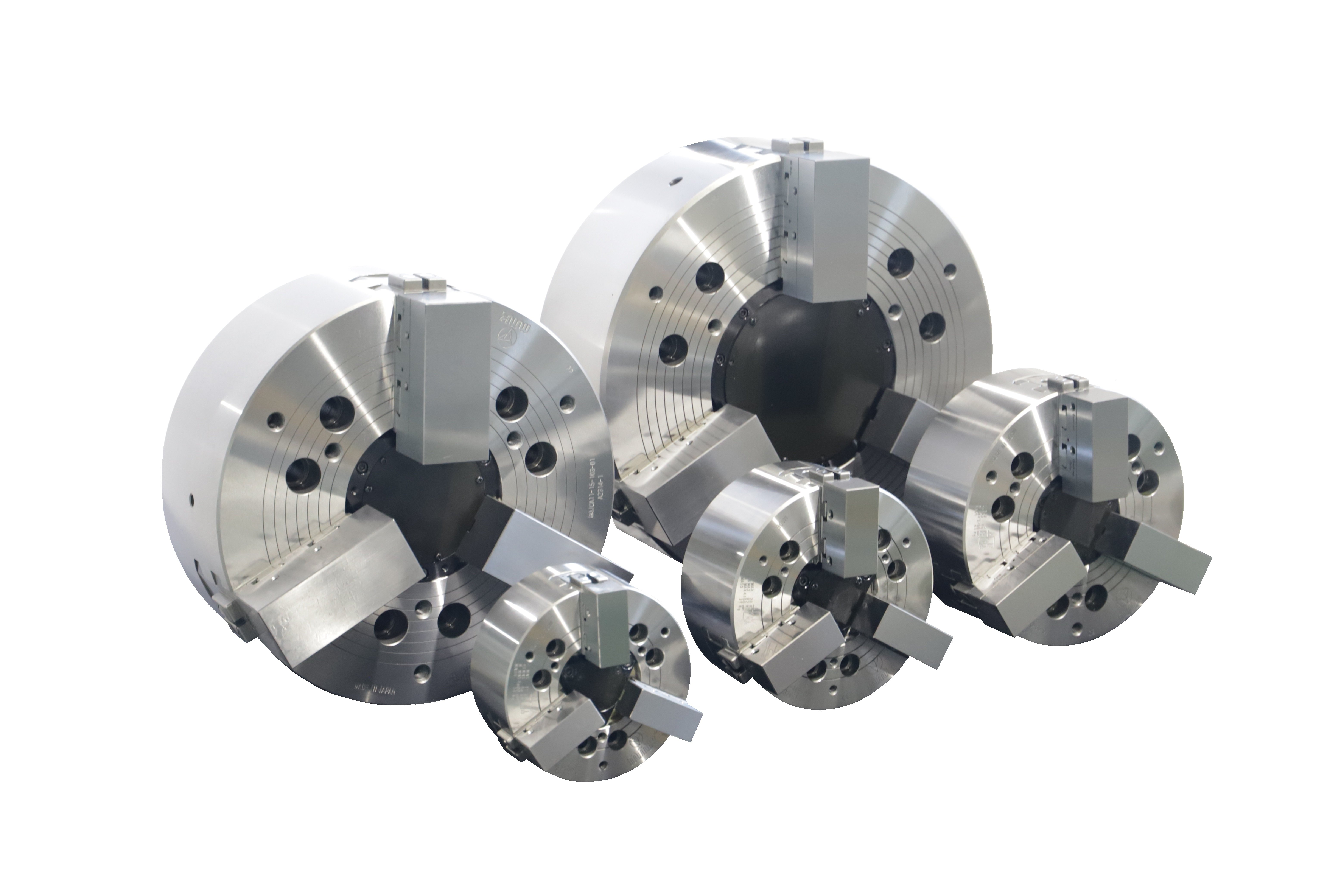

The company manufactures machine tool peripheral equipment such as lathe chucks, cylinders, rotary tables and various accessories, as well as providing technical information and services for these products.

The company has been exporting for more than 30 years, essentially in Asia and the USA, and during this time, they were able to build long-lasting and reliable relationships with many companies, including some of the world’s biggest aerospace and engine manufacturers. These partnerships have allowed them to innovate continuously, enhance their technological capabilities, and deliver superior quality products and services to their customers around the globe.

To access new markets, the company is now aiming to work together with potential partners in the EU providing an environment where the customers can use their products and services locally removing the distance barrier.

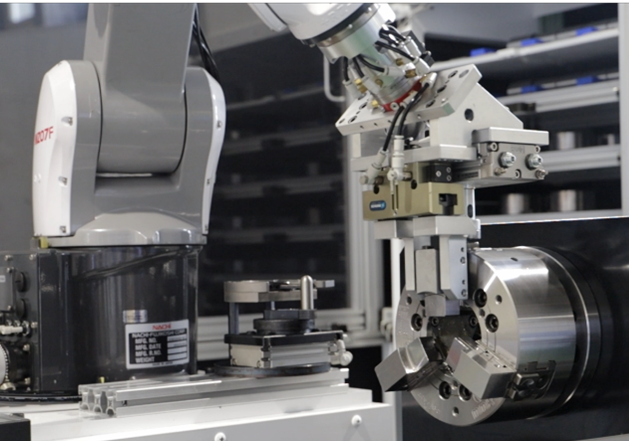

The potential partner is expected to go beyond the simple tasks of a dealer or distributor, providing technical services such as installation and/or maintenance.

The potential partner is expected to promote the products’ innovative aspects and to provide top class support maintaining customers satisfaction, mutual growth and success by building trust and integrity, therefore achieving market development as a result. The partner will be trained to handle the company products and after-sales services. - Advantages and Innovations

-

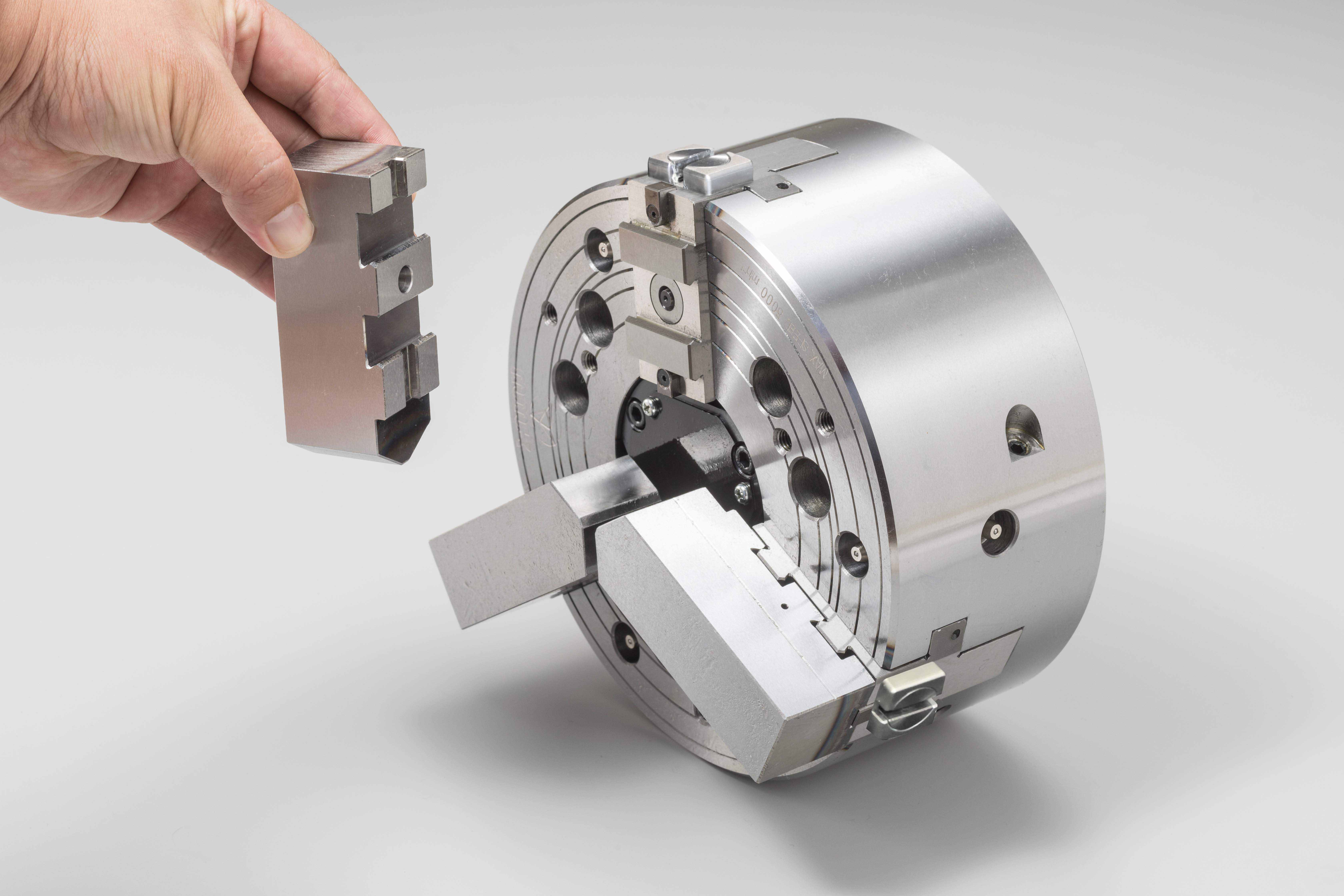

Proud of its replacement accuracy of 0.01 mm, the chuck features a special master jaw, which substantially decreases the amount of cutting chips getting inside, improves the chuck’s life and rigidity, and most importantly, reduces setup time from an average of 10 minutes to just 1 minute and eliminates the 20 minutes required for jaw forming. Assuming 3 to 5 jaw changes per shift, this innovation saves between 1.45 and 2.42 hours per shift. With an average cost of €38 per hour, this translates to a cost reduction of €55 to €92 per shift. With an average of 220 operational days per year, the annual savings per machine range from approximately €12,100 to €20,231, depending on the number of jaw changes.

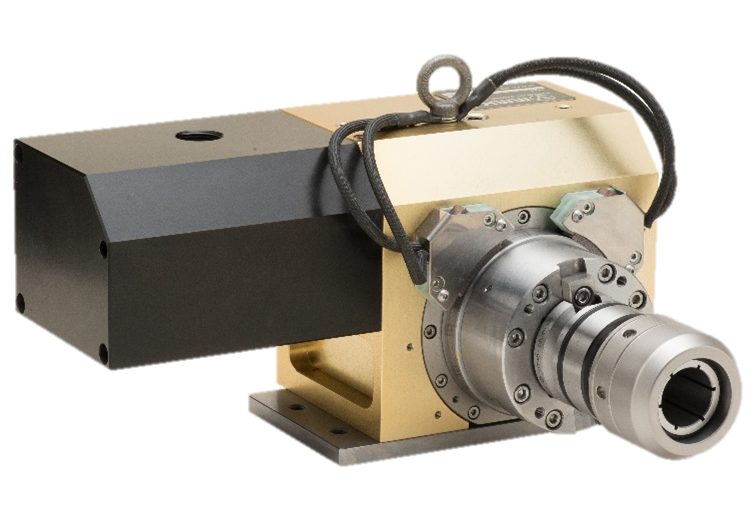

Additionally, they manufacture rotary tables for machining centres, wire cutting, drilling, and die-sinking EDM machines used in mould-making, precision machining, manufacturing of semiconductors, medical equipment and optical component as well as in combination with aircraft and automotive component manufacturing and 3D printers.

These are used in the machining of aircraft parts, contributing to the machining of fine holes and workpieces with complex shapes as the company holds an ISO9001 certification which allows them to manufacture products adopting for the aerospace industry.

Their EDM rotary tables implement a wide range of features: high-rigidity precision bearings, German-made worm and wheel gears, a wide tilting range of max. ±125°, current-collecting brushes, and, of course, water protection rating scale of IP68. These features improve stability, precision, and machine life while reducing maintenance costs.

These innovations offer substantial economic benefits to end users by reducing setup times increase machine utilisation, automatic jaw changes lower labour expenses, and enhanced product quality decreases scrap rates. Their solutions outperform prevailing products, providing significant savings and improved outcomes. - Sustainable Development Goals

- Not relevant

Partner Sought

- Expected Role of a Partner

-

The partner sought is a dealer, distributor or retailer in the sector of machine tools and peripheral equipment. Their expected roles would be:

- Promoting and marketing of the product supplied by the Japanese company

- Providing technical support to end-users, including after-sales service.

More specifically, following points are expected from a potential partner:

i. Sales track record: the partner company must have a solid customer base with past sales of machine tools and peripheral equipment.

ii. Technical skills: high level of technical knowledge and experience in machine tools and peripheral equipment, and the ability to provide appropriate support to customers.

iii. Marketing ability: knowledge of the market, ability to actively market and promote the products.

iv. After-sales service: the partner company must have a system in place to provide after-sales service that meets a customer’s needs.

v. Reliability and trustworthiness: a reliable partner, who honours contracts and builds long-term relationships. - Type and Size of Partner

- SME 11-49

- Big company

- SME <=10

- SME 50 - 249

- Type of partnership

- Commercial agreement

Dissemination

- Market keywords

- 09004008 - Other manufacturing (not elsewhere classified)

- Targeted countries

- All countries