Summary

- Profile Type

- Business Offer

- POD Reference

- BOJP20230127001

- Term of Validity

- 27 January 2023 - 26 January 2025

- Company's Country

- Japan

- Type of partnership

- Commercial agreementSupplier agreement

- Targeted Countries

- All countries

Contact the EEN partner nearest to you for more information.

Find my local partner

General information

- Short Summary

- A Japanese company is specialized in the production of industrial optical lenses used both in various industries and in academic facilities. They create high-quality, high-precision lightweight plastic lenses featuring a thin and efficient structure. The company wishes to proactively do business with EU partners to increase the market share of their products in the EU through a supplier or commercial agreement.

- Full Description

-

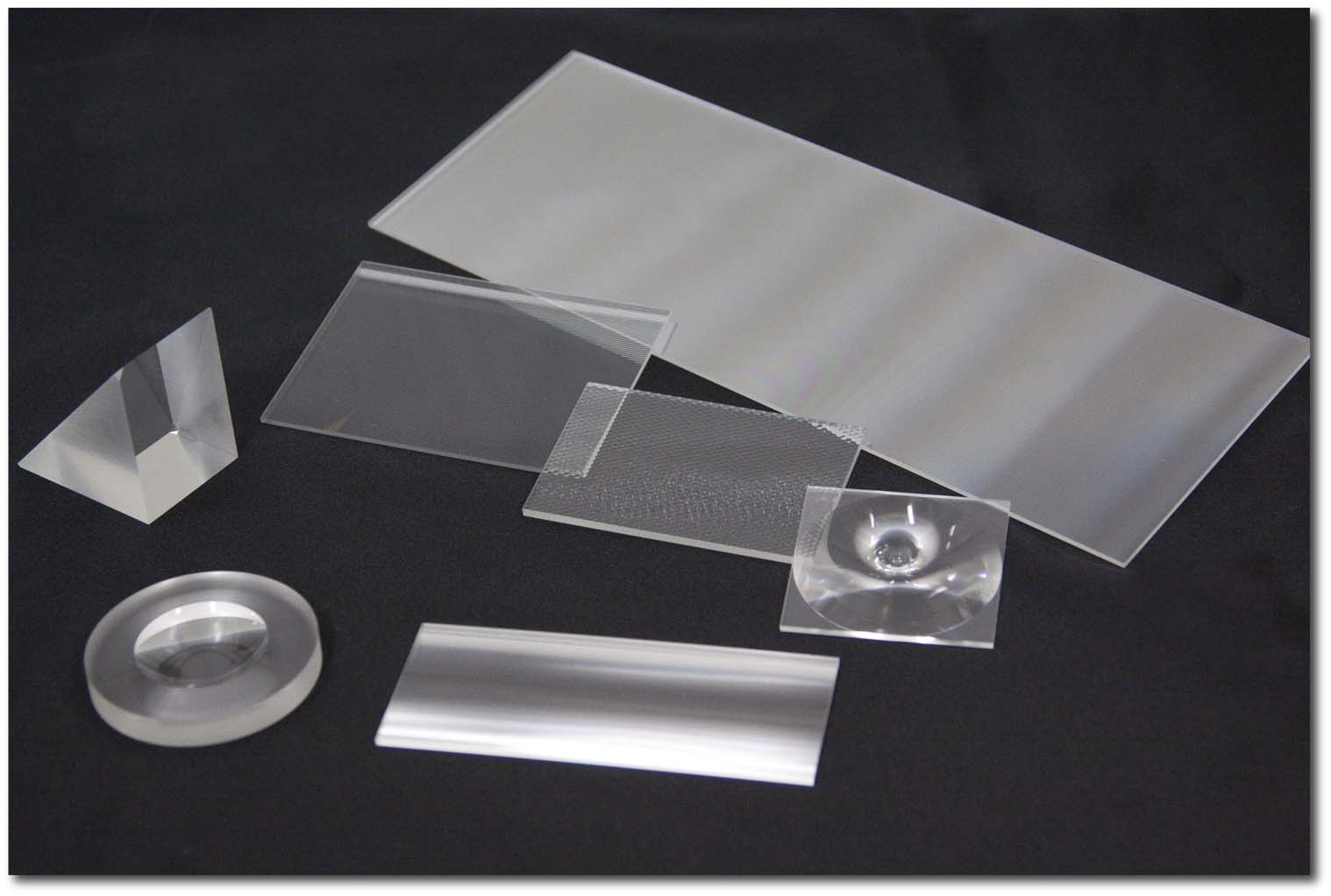

A Japanese company which started business in 1974 as a corporate entity manufacturing and selling high-quality, high-precision plastic lenses is looking for partners in the EU. They produce plastic optical products of practically any size, including Fresnel lenses, lenticular lenses, sheet prisms, linear Fresnel lenses, fly’s-eye lenses (Micro Lens Array – MLA), and aspheric lenses. Other products include diffraction grating, optical roll moulds, free-form surface lenses and elliptical lenses, spheric and aspheric lenses, UV (Ultraviolet) and IR (Infra-red) lenses, and light-guide plates.

The manufacturing expertise and equipment of the company can accommodate a broad range of customer needs, from prototype development to mass production.

Their proprietary lens machining equipment can craft lenses to microscopic tolerances, satisfying diverse requests and stringent specifications. They also manufacture customized machining equipment for mass production. For example, sheet lenses are marketed from sample quantities to mass production with heat compression, injection, extrusion with roll, roll-to-roll which material is generally PMMA (Poly Methyl Methacrylate) and PC (Poly Carbonate). It is also possible for them to offer lens moulds and moulded lenses, i.e., customised lenses.

The facilities at their factory are constantly being updated and expanded to include the latest technology and able to accommodate a variety of materials and thicknesses for prototype production or mass production of sheet moulding. Their parts are applied in many fields such as imaging, LED lighting, medical applications, sensing, augmented reality (AR), virtual reality (VR), aerospace, and astronomy. It is their firm belief that their distinctive capacity to produce a wide range of high-quality plastic lenses in various sizes in a timely manner will contribute to further research and development, and to the successful commercialization of customers’ products.

The company products have been in the international market for more than three decades and are highly valued for their precision and high quality.

Today, they are known around Japan and internationally as a top producer of lenses and are planning to expand their market share in the EU for their industrial lenses and usage in academic facilities. Relying on technological expertise and manufacturing know-how gained through decades of experience, they spare no effort in the discovery and application of new ideas when developing and creating microscopic, machined items. The satisfaction of their many customers magnifies their confidence in providing ideal solutions to customers’ most demanding problems. They would like to work with potential EU partners in the form of a supplier or commercial agreement. They offer potential partners their technical support, documentation, and other information where necessary. - Advantages and Innovations

-

*High Quality:

The company prides themselves on their high accuracy production line, beginning from optical design and mould creation to finished products and coating. Their engineers can help customers find or create the ideal product. They are eager to manufacture lenses of any type to conform to customers’ individual specifications.

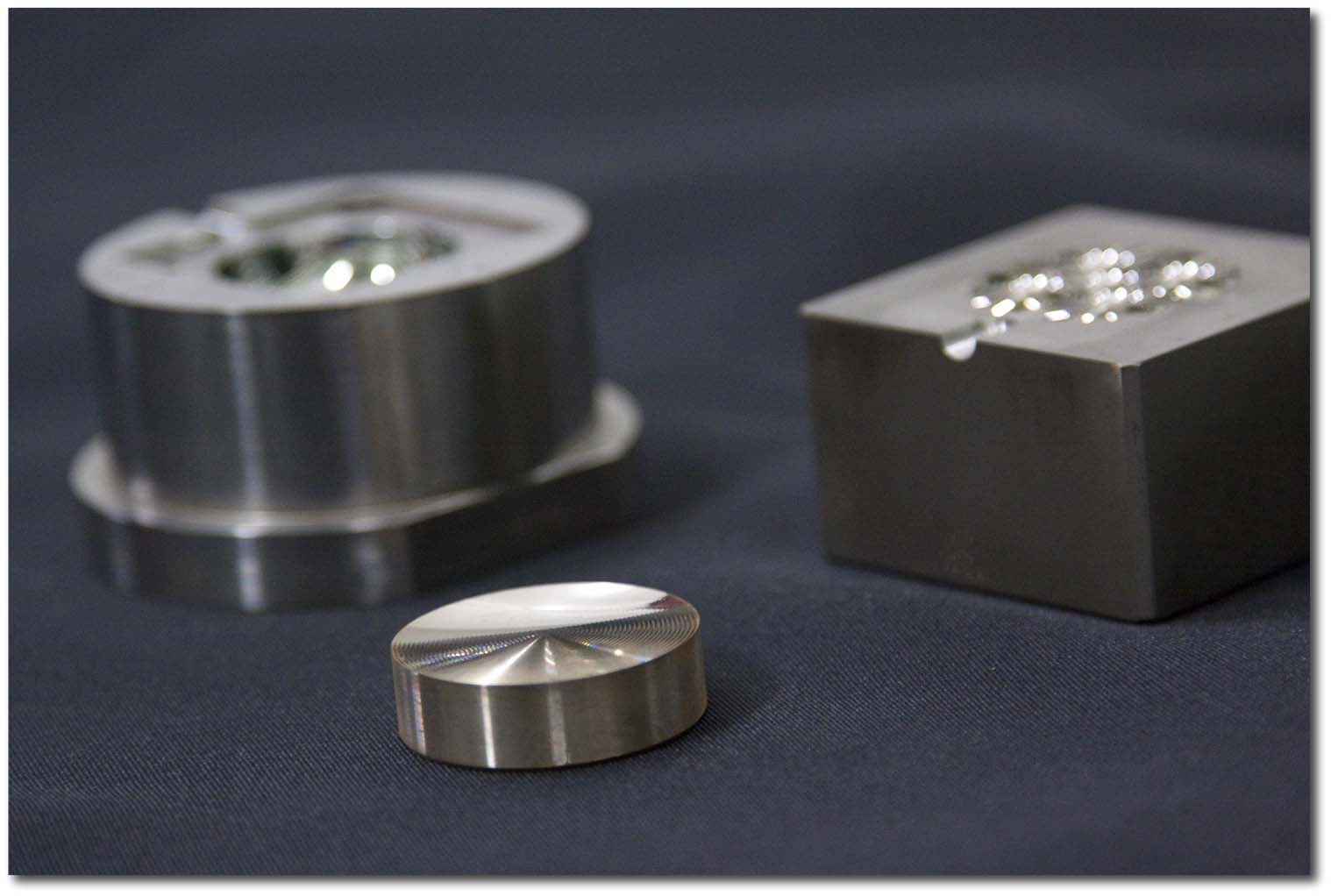

*Ultra-Precision Mould Manufacturing

Using their nano order single point diamond turning (SPDT) and machining, products with a resolution as low as 0.01 nano meter can be created. This extremely precise mould manufacturing enables their lenses to be used for various applications in various fields.

*Precise Heat Compression Moulding

Their high precision moulding technology is used to transfer fine optical patterns to various plastic materials such as PMMA or PC. Compared with conventional injection moulding, their precise heat compression moulding can create lenses that are larger, thinner and have more precise detail. Specifically, the radius of their lens peaks can be configured to be as low as 1 micron in size. They can obtain a mould-to-lens pattern transfer rate nearing 100%. It can also nearly precisely replicate the designed prism height of the lens peaks through heat-compression moulding methods, standing in contrast to the rounded lens peaks created by injection moulding methods. Their precise heat-compression minimizes the amount of light lost as it passes through the lens.

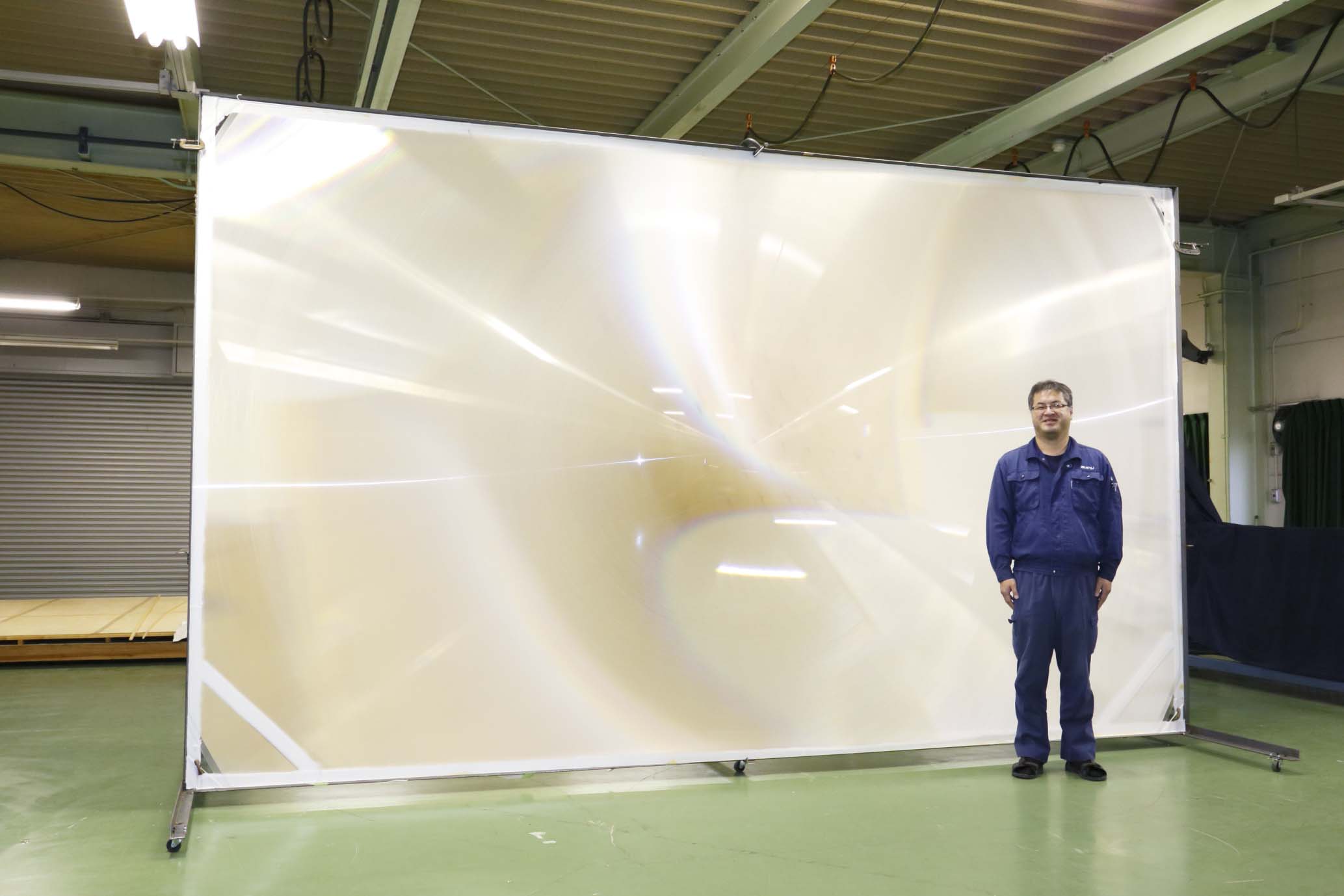

* Fresnel lenses

Recently, their flat prisms with finely ruled light guide panels are widely used in LCD (Liquid Crystal Display) backlight panels and Fresnel lenses are increasingly employed for magnification or collector lens applications. Their customized waveguides are also used for AR (Augmented Reality) /VR (Virtual Reality)/MR (Mixed Reality) applications. Large-scale transmission and reflective screens, with dimensions up to 200 inches, depend on their sophisticated Fresnel or lenticular lenses for the superior performance. - Sustainable Development Goals

- Not relevant

Partner Sought

- Expected Role of a Partner

- The Japanese company is looking for suppliers and commercial agents that have strong relationships and sales experience in optical markets in the EU. The ideal partner should have experience with optical technologies and be capable of understanding and explaining the products to potential end-users, either by representing the Japanese company or while supplying the product to end-users. It would be a plus if the potential partner has connections to academic institutions engaged in research on optical applications.

- Type and Size of Partner

- Big companySME 50 - 249SME <=10SME 11-49OtherUniversityR&D Institution

- Type of partnership

- Commercial agreementSupplier agreement

Call details

- Coordinator required

-

Yes

Dissemination

- Market keywords

- 08005 - Other Industrial Products (not elsewhere classified)

- Targeted countries

- All countries