Summary

- Profile Type

- Business Offer

- POD Reference

- BOPT20241031011

- Term of Validity

- 31 October 2024 - 31 October 2025

- Company's Country

- Portugal

- Type of partnership

- Outsourcing agreement

- Supplier agreement

- Targeted Countries

- All countries

Contact the EEN partner nearest to you for more information.

Find my local partner

General information

- Short Summary

- The Portuguese company is a specialist in the supply of iron castings, technical parts and able to machine cast parts for numerous sectors, from railways (catenary equipment) to pump industry (pumps, carters), nautics (compressors, motor supports), agriculture (machinery) and defence, among others. The SME is keen to expand its activity further and seeks new partners for collaboration on the basis of manufacturing agreements

- Full Description

-

Having been operational since the 1936’s, the Portuguese company takes pride in using modern engineering techniques with traditional iron casting skills to deliver high quality technical parts, iron casted parts (grey iron and ductile alloys) and machined parts (iron, steel, copper, aluminum, other supports) to all of their clients in Portugal and beyond. All design, engineering, casting, monitoring and validation services are in-house, including machining, finishing and assembly.

The company is continuously growing and building on its solid reputation for producing high-quality globally recognized metal castings, machining and technical parts for over 88 years and is the ideal one-stop-shop for castings requirements.

Capitalizing on traditional foundry skills, linked to state-of-the-art technology and production processes, the company has an exclusive industrial unit for casting, producing grey and ductile cast iron parts of various alloys and is prepared to deliver, small, medium and large series. The batch dimensions and the weight of the castings define the appropriate moulding line. The automatic moulding process delivers medium and large series up to 90 kg and moulding flasks of 800 x 600 x (250 + 250) mm. As for the self-dry moulding process, the firm produces small and medium batches of parts up to 500 kg, with moulding flasks with maximum dimensions of 1300 x 1200 x (400 + 400) mm. Castings can be supplied with heat treatment and protected with primer against rust-

As far as the iron foundry is concerned, the company uses the following equipment:

Inductotherm induction furnace (3 ton/h)

Cold box and CO2 core shop

BMD automatic moulding line (up to 90 moulds/h)

IMF no-bake moulding line (up to 15 ton/h)

2 CM shot blasting stations

GF sand testing range

Spectro spectrometer

Hoytom tensile strength tester

Dust and fumes extraction (250kw)

Atlas Copco compressed air system with 2 compressors, filter and air dryer

Emergency power generator

3D Measuring machine - MITUTOYO FJ905 (900X550X450) mm

Automatic deburring centre LIANCOGS70

Equally important, the team delivers precision machining of castings from multiple foundries (eg, iron, steel, copper and aluminium), with the possibility of machining small, medium and large series, ensuring that each machined part meets precision standards trough a metrological laboratory specialised in dimensional control, with the capacity to complement the inspections carried out at production sites and to check the precision of each part produced. Through Computerised Numerical Control (CNC) mahinery, the team ensures minimum tolerances and high-precision finishes.

The machining shop uses the following equipment:

- Multi-function machining center OKUMA MULTUS (B400W & U3000)

- Machining centre MAZAK FH4800

- Machining centre MITSUI SEIKI ( H6C & HT4A)

- Machining centre DMG MORI NHX 10 000

- Machining centre MAKINO A500Z

- 3D coordinates Measuring machine – Zeiss Contura RDS-CAA

The company provides a fully accountable system according to ISO 9001 and Overall Equipment Effectiveness monitoring. Each item that leaves their production line has the CE mark of quality.

The firm now plans to grow the international side of its business and is seeking requests for manufacturing agreements with partners who are looking for a quality one-stop production partner. - Advantages and Innovations

-

The Portuguese company can offer the following advantages to a potential partner:

- Continual investment in advanced technology, state-of-the-art equipment and training.

- High-quality machining, specialising in technical parts made from any metal alloy.

- Quality team of highly experienced workers to deliver precision parts adapted to the needs of manufacturers of small and medium series capital goods.

- Quality assurance guaranteed (ISO 9001:2015 Certificate in respect of its Quality Management Procedures);

- Tight control of the chemical composition (fusion is obtained in an induction furnace, supported by spectrometer).

- A bespoke in-house service that ensures that every stage of each design project is tracked and documented thoroughly. - Stage of Development

- Already on the market

- Sustainable Development Goals

- Goal 7: Affordable and Clean Energy

- Goal 12: Responsible Consumption and Production

- IPR status

- IPR granted

- IPR notes

-

Copyright

Patent(s) applied for but not yet granted

Design Rights

Patents granted

Trademarks

Partner Sought

- Expected Role of a Partner

- The Portuguese company is seeking potential partners with requirements for the fabrication of iron casted parts (grey iron and ductile alloys) and machined parts (iron, steel, copper, aluminum and other supports). The partnership is envisaged under an outsourcing/manufacturing agreement.

- Type and Size of Partner

- SME 50 - 249

- Big company

- Type of partnership

- Outsourcing agreement

- Supplier agreement

Dissemination

- Market keywords

- 08001012 - Speciality metals (including processes for working with metals)

- 08003001 - Machine tools, other metal working equipment (excl. numeric control)

- 08003007 - Other industrial equipment and machinery

- Targeted countries

- All countries

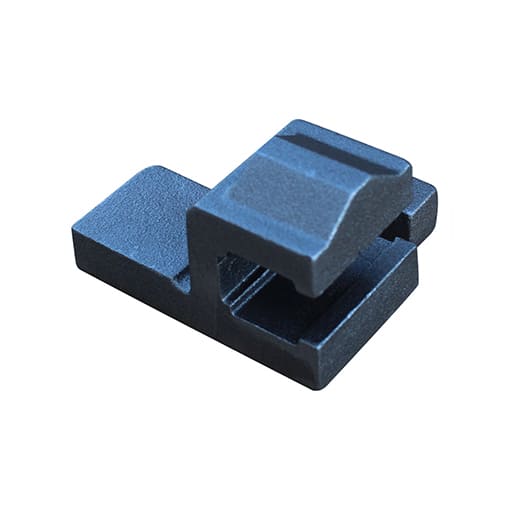

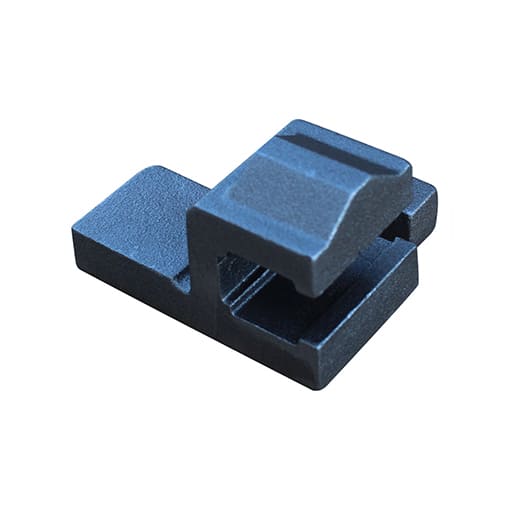

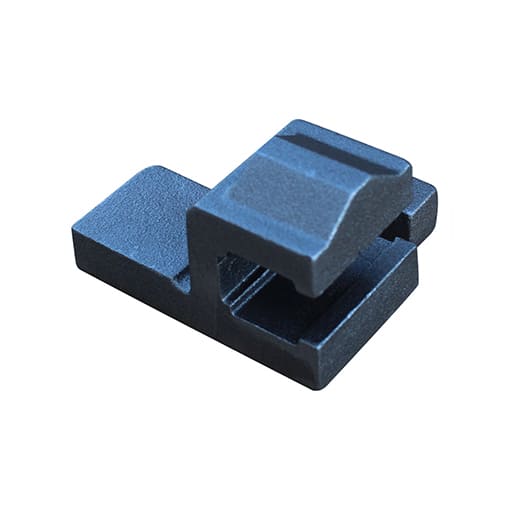

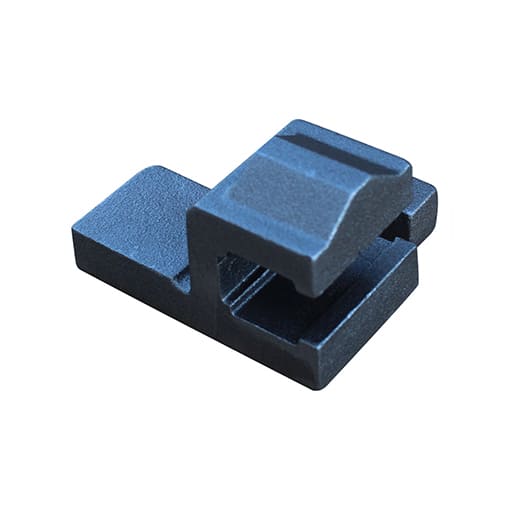

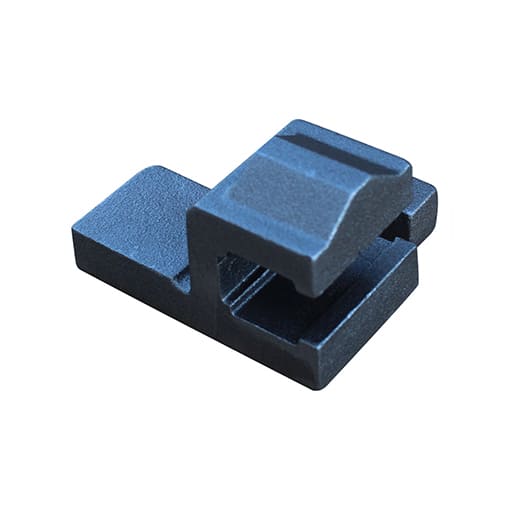

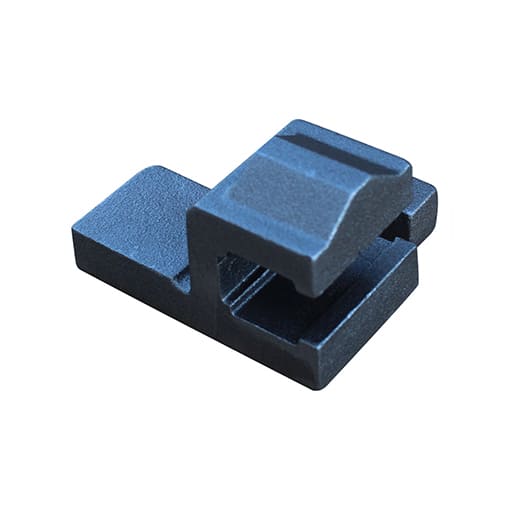

Images

Iron foundry and machining

Iron foundry and machining

Iron foundry and machining

Iron foundry and machining

Iron foundry and machining

Iron foundry and machining

Iron foundry and machining

Iron foundry and machining

Iron foundry and machining

Iron foundry and machining

Iron foundry and machining

Iron foundry and machining

Iron foundry and machining

Iron foundry and machining

Iron foundry and machining

Iron foundry and machining

Iron foundry and machining

Iron foundry and machining

Iron foundry and machining

Iron foundry and machining

Iron foundry and machining

Iron foundry and machining

Iron foundry and machining

Iron

Iron

Iron

Iron

Iron

Iron

Iron

Iron

Iron

Iron

Iron

Iron

Iron foundry and machining

Iron foundry and machining

Iron foundry and machining

Iron

Iron

Iron

Iron

Iron

Iron

Iron

Iron

Iron

Iron

Iron

Iron

Iron

Iron

Iron

Iron

Iron

Iron

Iron

Iron

Iron foundry and machining

Iron