Summary

- Profile Type

- Technology offer

- POD Reference

- TODE20230913019

- Term of Validity

- 13 September 2023 - 12 September 2025

- Company's Country

- Germany

- Type of partnership

- Investment agreement

- Research and development cooperation agreement

- Targeted Countries

- All countries

Contact the EEN partner nearest to you for more information.

Find my local partner

General information

- Short Summary

- The invention of a German university describes a new manufacturing process for GRIN (Gradient index lenses) plastic optics, in which extruded films with a defined refractive index gradient are rolled up and sintered. This makes it possible to manufacture lenses with any aperture and adjustable refractive index variation.The university offers a license and a technology cooperation agreement.

- Full Description

-

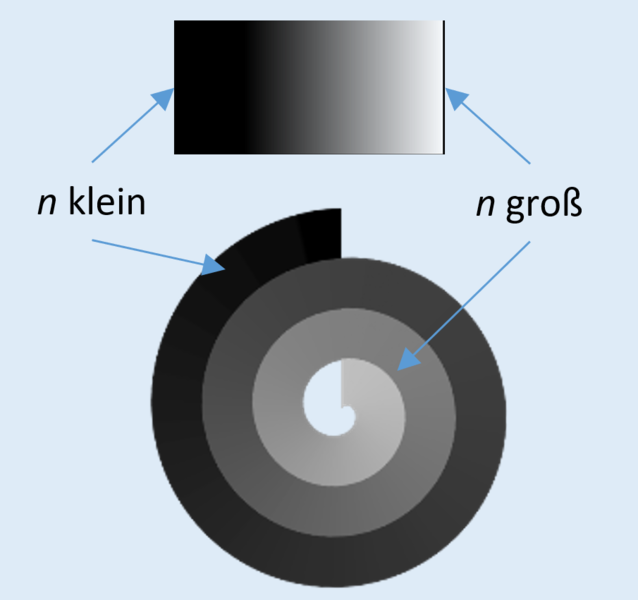

Classical lenses are made of an optical material with a certain refractive index and curvature. These two characteristics determine the lens’s focal length. An alternative design is achieved by varying the refractive index radially and using a curved surface.

Scientists from a German university have developed a new manufacturing process for gradient lenses. It achieves optical element refractive power not with curvature, but by such means as radially varying the lens material refractive index. The lens can then take the simple geometric shape of a cylinder with parallel surfaces.

So far, such lenses have been manufactured from special pieces of glass with ion exchange in immersion baths so that the diffusion from the edge creates a gradient in the material. This process is painstaking and expensive.

The invention now allows cylinder lenses to be manufactured from plastic, with the cylinder wrapped from film with index gradients along its length that then translate to a radial progression. A tempering step then produces continuous material properties. The film gradient can be achieved with co-extrusion of two different polymers with a temporally variable mixer.

The university offers a license agreement to companies from the eyewear and lenses industry as well as lens manufacturers. If there is interest in further development of the process, the university also offers technological cooperation. - Advantages and Innovations

-

The main advantages and innovative aspects of this invenation are:

- Thinner or flatter lens of the same focal length

- Lower aberrations (coma, chromatic aberration)

- Unique, affordable manufacturing process for GRIN with large aperture

- Film extrusion followed by wrapping

- This technology profile is based on a summary provided by the inventors (see Appendix). - Stage of Development

- Lab tested

- Sustainable Development Goals

- Goal 9: Industry, Innovation and Infrastructure

- IPR status

- IPR applied but not yet granted

- IPR notes

- A patent application has been submitted to the German Patent and Trade Mark Office. Within the priority year, PCT and U.S. applications were also submitted.

Partner Sought

- Expected Role of a Partner

- The university offers a license agreement to companies from the eyewear and lenses industry as well as lens manufacturers. If there is interest in further development of the process, the university also offers technological cooperation.

- Type and Size of Partner

- Big company

- SME 50 - 249

- Other

- SME 11-49

- SME <=10

- Type of partnership

- Investment agreement

- Research and development cooperation agreement

Dissemination

- Technology keywords

- 03002 - Process Plant Engineering

- 03004008 - Plastics and Rubber related to Chemical Technology

- 05003002 - Optics

- Market keywords

- 05007007 - Other medical/health related (not elsewhere classified)

- 04005 - Biochemistry / Biophysics

- Targeted countries

- All countries