Summary

- Profile Type

- Technology offer

- POD Reference

- TOAT20250514013

- Term of Validity

- 3 June 2025 - 3 June 2026

- Company's Country

- Austria

- Type of partnership

- Research and development cooperation agreement

- Commercial agreement with technical assistance

- Targeted Countries

- All countries

Contact the EEN partner nearest to you for more information.

Find my local partner

General information

- Short Summary

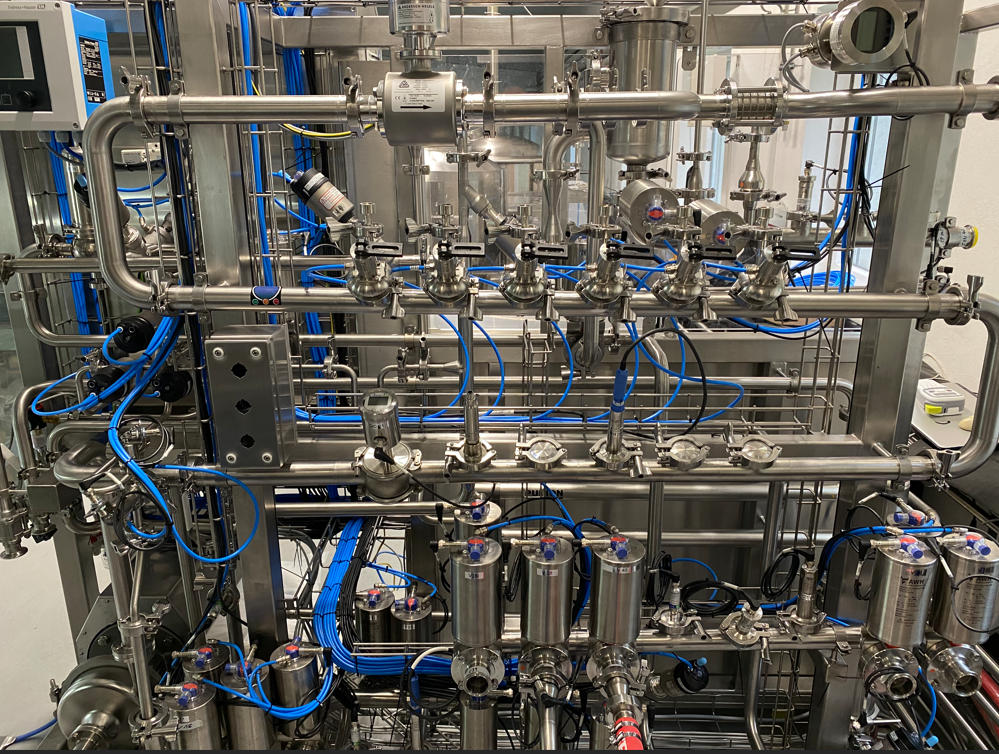

- An Austrian spinoff invented a highly efficient tool for the upscaling of fermentation processes: the innovation was created by arranging all components of a bioreactor system into a separate, mobile tool for bioreactor operations and thus combining this sophisticated bioreactor infrastructure with simple low-cost fermenters via a by-pass system. It can be applied in the production of microbially produced food and quickly lead to industrial production scale. Commercial or R&D cooperation sought.

- Full Description

-

The problem is that the upscaling of bioprocesses (involving oil, fats, proteins, biochemicals…) based on yeast/bacteria/fungi from lab to production scale requires enormous investments and a lot of time. In addition, several different bioreactor sizes are required. Upscaling is one of the biggest challenges for developers and especially startups. State-of-the-art bioreactors as they are built for pharmaceutical applications are far too expensive. Furthermore, traditional beer brewing technologies and equipment are too simple for new, productive, specialised microbes.

The Austrian spinoff from a traditional brewery and fermentation equipment manufacturer with over 35 years of experience invented a sterile, highly economic system that can operate several bioreactor sizes, using low cost/existing tanks which are transformed with the help of this module into highly sophisticated bioreactors. Therefore, all the technical equipment required for a bioreactor is integrated into a mobile unit and low-cost tanks of different sizes are turned into bioreactors with the help of a bypass system. The tool is simply moved to a suitable stirred vessel of any size (connectable with 3 vessels simultaneously) and these vessels are turned into fully equipped bioreactors, even a complete bioprocess pilot plant.

It is very compact and robust, fits through most doors and provides a safe workplace without stairs or ladders. It allows user-friendly maintenance of sensors and dosing pumps and has well-stored auxiliary containers under the console.

The module can be combined with

- tanks for substrate preparation, propagation, production-bioreactor (100 – 20,000 l),

- flash pasteurization (500-2,000 l/h) for end product,

- single-pipe heater or cooler (20-200 kW) for tanks-CIP (cleaning in place) and substrate pasteurization, from batch to fed batch to continuous processes and others.

The company also offers an agitator for the bioreactors that completes the process on a low cost and low energy basis. Partners to commercialise and exploit the patent, which is not granted yet, are sought. They may come from various sectors, e.g. pharmaceutics, chemistry, food or any others that need upscaling of fermentation processes. - Advantages and Innovations

-

• high tech solution for easy upscaling of bioprocesses from lab to production

• low cost

• compact (frame: 1,400 x 1,000 x 1,900 mm) - fits through most doors

• robust

• flexible

• smart module

• all-in-one

• Plug & Play

• safe workplace without stairs or ladders

• allows user-friendly maintenance of sensors and dosing pumps and has well-stored auxiliary containers under the console - Stage of Development

- Available for demonstration

- Sustainable Development Goals

- Goal 2: Zero Hunger

- IPR status

- IPR applied but not yet granted

- IPR notes

- Patents applied for EU, UK, USA, India, China

Partner Sought

- Expected Role of a Partner

- The company is actively seeking partners to commercialize and maximize the potential of the patent. These partners could be from diverse sectors such as pharmaceuticals, chemistry, food, or any other industries that require scaling up their operations.

- Type and Size of Partner

- SME 50 - 249

- SME <=10

- University

- Big company

- R&D Institution

- SME 11-49

- Type of partnership

- Research and development cooperation agreement

- Commercial agreement with technical assistance

Dissemination

- Technology keywords

- 06006011 - Fermentation

- 06006012 - Bioprocesses

- 08001005 - Food Technology

- 08001004 - Food Processing

- Market keywords

- 08003007 - Other industrial equipment and machinery

- 04007 - Enzymology/Protein Engineering/Fermentation

- Targeted countries

- All countries