Summary

- Profile Type

- Business Offer

- POD Reference

- BOPL20240821011

- Term of Validity

- 21 August 2024 - 21 August 2025

- Company's Country

- Poland

- Type of partnership

- Outsourcing agreement

- Targeted Countries

- Austria

- Germany

- Netherlands

Contact the EEN partner nearest to you for more information.

Find my local partner

General information

- Short Summary

-

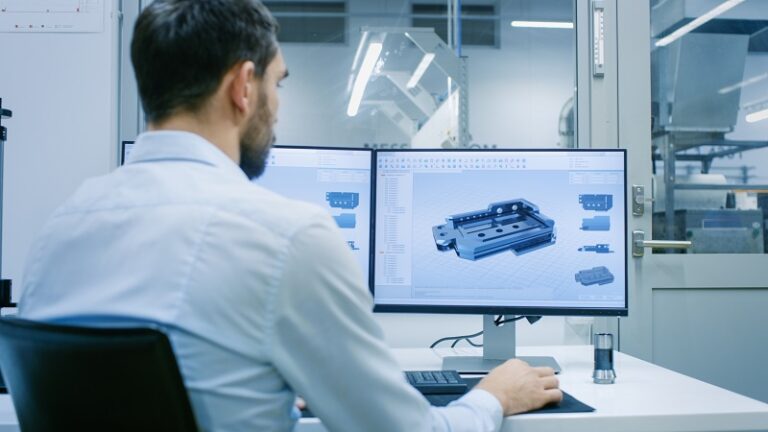

A Polish company has strong potential and modern machinery for professional sheet metal processing (laser cutting, CNC bending, punching, laser welding, design, and production). Their products are high-quality with original, functional designs, using the best materials and suppliers.

The company is looking for manufacturer form Germany, Austria and Netherlands using metal elements. - Full Description

-

The company has a very large potential and capabilities with modern machinery facilities, which deals, among others, with professional sheet metal processing ( laser cutting, CNC sheet metal bending, sheet metal punching, laser welding, product designing, production). Their products are characterized by high quality, original and functional design. They use the best materials. They work with the best suppliers.

Their services:

I. LASER CUTTING They have a modern fiber laser cutting machine with a power of 3 kW. The maximum size of the processed sheet is 1500x3000 mm. - carbon steel up to 16 mm thick - stainless steel up to 12 mm thick - galvanized steel up to 3 mm thick - aluminum up to 8 mm thick.

II. PUNCHING The use of a punching machine is ideal for elements with many holes (perforation). In the case of punching elements from galvanized steel, the process causes zinc to be drawn onto the cut edges. Thanks to this, the elements have greater resistance to corrosion. In addition to cutting complex shapes, we can also perform dense perforation, small embossing and threading. They cut sheets up to 4 mm thick. The maximum sheet size is 1250x2000 mm.

III. METAL BENDING Using their numerically controlled press brake, we can bend elements with a maximum length of up to 3000 mm. The press pressure of 100 tons allows you to bend elements up to 10 mm.

IV. LASER WELDING AND LASER CLEANING They have a modern welding and cleaning machine with a power of 2 kW. Laser welding allows them to join very thin materials without causing them to deform.We weld thicker materials up to 5 mm. The laser enables excellent welding quality. It is also possible to weld without the use of filler metal. Laser cleaning allows for very quick removal of rust, carbon deposits, paints, oils, etc.

V. 2D/3D CAD DESIGNING Many years of experience of their engineers and technologists allow us to design very complex elements using 2D/3D CAD programs. They also create visualizations of finished products.

VI. ASSEMBLY OF COMPONENTS They connect previously produced components by riveting, welding and screwing. The finished product is packed according to the customer’s instructions.

The company is looking for manufacturer using metal elements.

Manufacturing and subcontracting are types of consider agreements. - Advantages and Innovations

-

Quality and punctuality

At each stage of the production of a product, they carefully check the compliance of the dimensions with the documentation and the quality of workmanship. Thanks to our experienced specialists and modern machinery, they are able to complete your order with the highest accuracy and within the agreed time.

Comprehensiveness of the service provided

Orders can be complete comprehensively, starting from the design with visualization, through cutting and bending sheet metal, powder coating, to assembly and packaging of the finished product.

Customer service

Their team consists of qualified specialists who provide comprehensive service and execution of your order in accordance with the highest quality standards. Thanks to their knowledge and experience, cusromers can be sure that your order will be completed professionally, precisely and in accordance with the documentation. - Stage of Development

- Already on the market

- Sustainable Development Goals

- Not relevant

- IPR status

- Secret know-how

Partner Sought

- Expected Role of a Partner

- Manufacturer using metal elements will order sheet metal requiring specialized mechanical processing.

- Type and Size of Partner

- SME <=10

- SME 11-49

- SME 50 - 249

- Type of partnership

- Outsourcing agreement

Dissemination

- Technology keywords

- 02002010 - Machining (turning, drilling, moulding, planing, cutting)

- 02002009 - Machine Tools

- Market keywords

- 08003001 - Machine tools, other metal working equipment (excl. numeric control)

- Targeted countries

- Austria

- Germany

- Netherlands