Summary

- Profile Type

- Technology offer

- POD Reference

- TODE20230608014

- Term of Validity

- 8 June 2023 - 7 June 2025

- Company's Country

- Germany

- Type of partnership

- Commercial agreement with technical assistance

- Targeted Countries

- Italy

- Portugal

- Spain

- Switzerland

- Norway

- Netherlands

- Poland

- France

- Sweden

- Denmark

- United Kingdom

- Czechia

- United States

- Belgium

- Greece

- Canada

- Austria

Contact the EEN partner nearest to you for more information.

Find my local partner

General information

- Short Summary

-

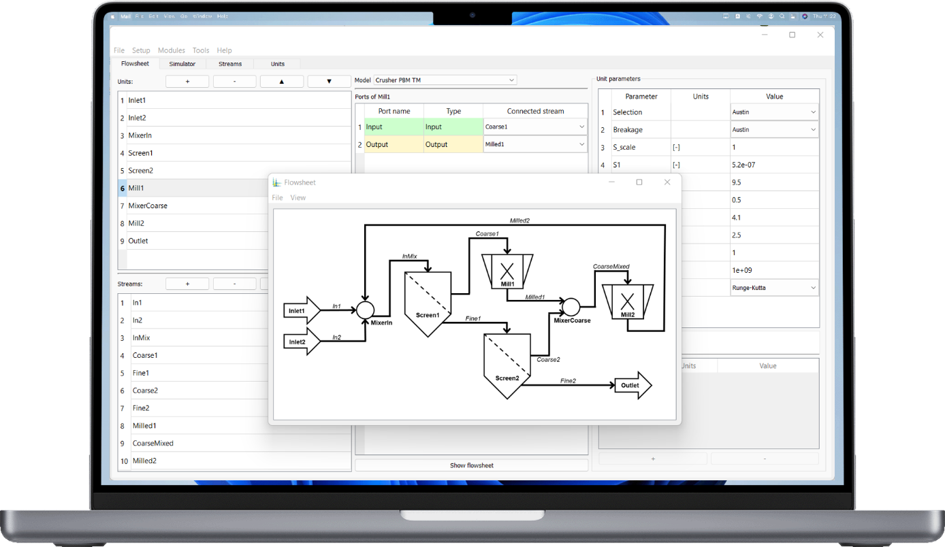

A German Startup has developed a digital twin software to simulate industrial solids processes.

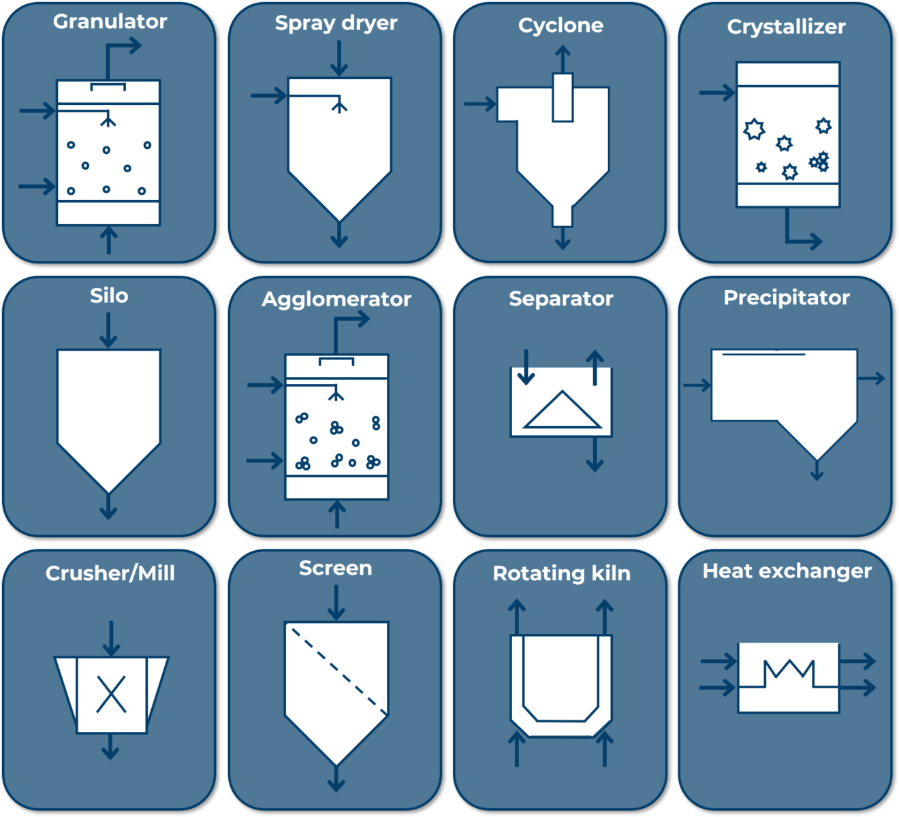

This process simulation tool digitally reproduces the behaviour of solids, e.g. during different production stages. It can be used to enable seemless optimization, simulate changes, and develop control strategies or even to design brand new products.

The solution contains battle tested process simulation units that are already being used by research- and industry partners since several years. - Full Description

-

Today’s process optimisation in the food-, chemical-, agriculture-, mining- or pharma industry is oftentimes carried out on running production lines, resulting in downtimes that can generate high loss of turnover (e.g. costs between 20 und 200k per hour in the chemical and fast moving consumer goods sector).

The simulation software enables research and development departments to create digital process twins, that enable manufacturers to significantly reduce downtimes.

The process simulation software focuses on modelling solids processes. The challenge here is related to the interdependence of such distributed particle properties as size, shape or moisture, which the software can handle by design.

This allows for better management of ongoing optimisation, e.g. for product development or to define an agile response to changes in the supply chain.

In addition, the modelling framework allows the simulation of dynamic processes to investigate their stability, start-up and shut-down behaviour in continuous, batch and semi-batch modes.

The simulation software comes with a set of basic process models already implemented and ready-to-use. A basic version is open source. Based on this, the company offers individual consulting and specific model development.

The company continuously improves and extends the simulation units through a feedback loop between the development team and the users. This includes development and implementation of custom process models. - Advantages and Innovations

-

The software enables the simulation of a digital twin that allows for simplified process optimization. Thus, the optimization does not have to be developed and tested on the running system.

Process simulation with bulk materials is very complex since every single particle has its own size, shape and moisture content or composition. The simulation software enables multiple bulk properties besides the size distribution.

The solution provides the possibility to consider time-dependent process behaviour by default.

Each unit is solved individually, which makes it possible to describe very complex units for which equation-oriented frameworks are not capable.

The Model Maker Tool can be used to code own models that perfectly represent individual processes.

The open-source base version is available for free. The source code can be customized with little C++ knowledge. - Stage of Development

- Already on the market

- Sustainable Development Goals

- Goal 9: Industry, Innovation and Infrastructure

- Goal 12: Responsible Consumption and Production

- IPR status

- Secret know-how

Partner Sought

- Expected Role of a Partner

-

Research and Development departments of several manufacturing industries that process or produce solids with a particular form (e.g. from the food-, chemical-, agricultural-, mining- and pharmaceutical industry).

Currently, the focus is especially on larger companies with research and development departments, ideally with a simulation department.

In the future, the software will be further developed, so that a single machine operator can directly use it. - Type and Size of Partner

- Big company

- SME 50 - 249

- Type of partnership

- Commercial agreement with technical assistance

Dissemination

- Technology keywords

- 01004011 - Maintenance Management System

- 02004 - Plant Design and Maintenance

- 01003013 - Information Technology/Informatics

- 01003016 - Simulation

- 02001 - Design and Modelling / Prototypes

- Market keywords

- 08006001 - Process control and logistics

- 08002003 - Process control equipment and systems

- 08002007 - Other industrial automation

- Sector Groups Involved

- Digital

- Energy-Intensive Industries

- Agri-Food

- Targeted countries

- Italy

- Portugal

- Spain

- Switzerland

- Norway

- Netherlands

- Poland

- France

- Sweden

- Denmark

- United Kingdom

- Czechia

- United States

- Belgium

- Greece

- Canada

- Austria