Summary

- Profile Type

- Business Offer

- POD Reference

- BOTR20250604002

- Term of Validity

- 4 June 2025 - 4 June 2026

- Company's Country

- Turkey

- Type of partnership

- Supplier agreement

- Commercial agreement

- Investment agreement

- Targeted Countries

- All countries

Contact the EEN partner nearest to you for more information.

Find my local partner

General information

- Short Summary

- Company has a wide production capacity and knowhow about die design ,tool design ,hot forged parts and holders specialised in machinery, automotive and aviation industries.

- Full Description

-

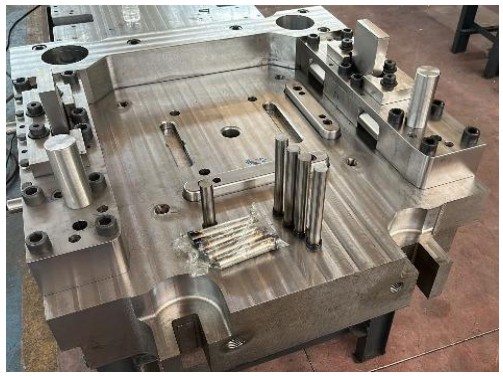

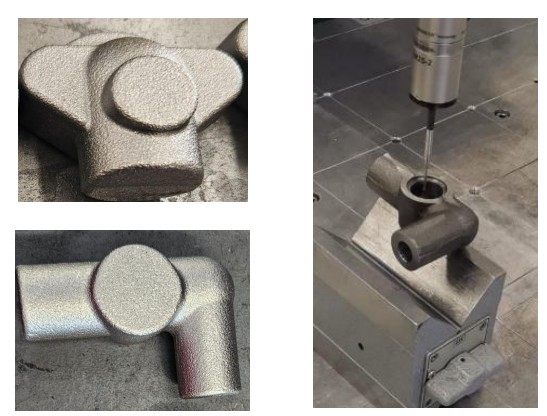

Company has an office in ULUTEK technology center for R-D facilities and Machinery lay out established in Bursa Yalıntas Industrial Zone. They supply forgings in different conditions; such as raw forging conditions, raw machined and final machined.

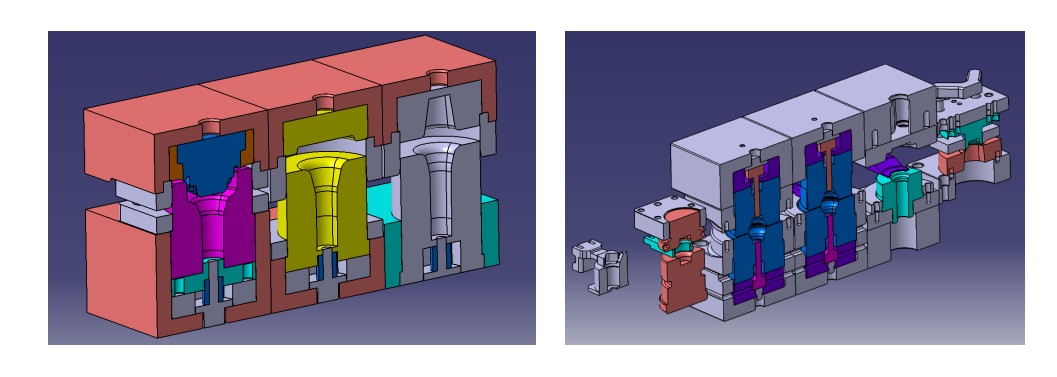

Company provides support for the forging model designs of the parts of all sectors, tolerances according to the EN 10243 forging standard, creating the forging technical drawing, as well as the forging die design, forging simulation and the creation of the forging process.As a co-designer on final part design, work with customers such as OEM and Tier1 to produce solutions for the parts whose design is completed, together with finite element analysis.

Also providing support in many different subjects such as improving the mold life, forging process adaptation, machining fixture design (mechanical and hydraulic) and reducing machining times, which will contribute to the improvement works of all companies.

Forged parts in series produced by using raw materials such as steel, aluminum, titanium, super alloy Inconel, especially for the automotive, agriculture, railway, heavy vehicle (trucks), energy sector, industrial valve and defense/aviation industry.

Also performing controlled cooling, QT, isothermal annealing for steels, and T6 heat treatment (solution + aging) for aluminums, according to the customer's request, for the forged parts.

In addition, according to the customer's request, cathopheresis coating, zinc nickel plating, pickling and passivation operation for stainless steels and pickling operation for aluminum are provided for the steel parts whose heat treatment has been completed.

Laboratory and quality reports are carried out in full for the parts whose forging, heat treatment and coating processes are completed according to the customer's requests. - Advantages and Innovations

-

Design and RD Facilities

Sectoral and Materials Know how

Prototype and Simulation of Processes

Coating and Laboratory Facilities - Technical Specification or Expertise Sought

- Hot Forge Die Precision

- Stage of Development

- Already on the market

- Sustainable Development Goals

- Goal 9: Industry, Innovation and Infrastructure

- IPR status

- No IPR applied

Partner Sought

- Expected Role of a Partner

- Companies in automotive, agriculture, railway, heavy vehicle (trucks), energy sector, industrial valve and defense/aviation industries using hot forged parts

- Type and Size of Partner

- SME 11-49

- Big company

- SME 50 - 249

- SME <=10

- Other

- R&D Institution

- Type of partnership

- Supplier agreement

- Commercial agreement

- Investment agreement

Dissemination

- Technology keywords

- 02002009 - Machine Tools

- 02002006 - Hardening, heat treatment

- 02002005 - Forming (rolling, forging, pressing, drawing)

- 02002015 - Surface treatment (painting, galvano, polishing, CVD, ..)

- Market keywords

- 08001015 - Other speciality materials

- 08001009 - Speciality/performance materials: producers and fabricators

- 08001012 - Speciality metals (including processes for working with metals)

- Sector Groups Involved

- Energy-Intensive Industries

- Targeted countries

- All countries