Summary

- Profile Type

- Business Offer

- POD Reference

- BOBE20240903014

- Term of Validity

- 3 September 2024 - 3 September 2025

- Company's Country

- Belgium

- Type of partnership

- Commercial agreement

- Investment agreement

- Targeted Countries

- All countries

Contact the EEN partner nearest to you for more information.

Find my local partner

General information

- Short Summary

-

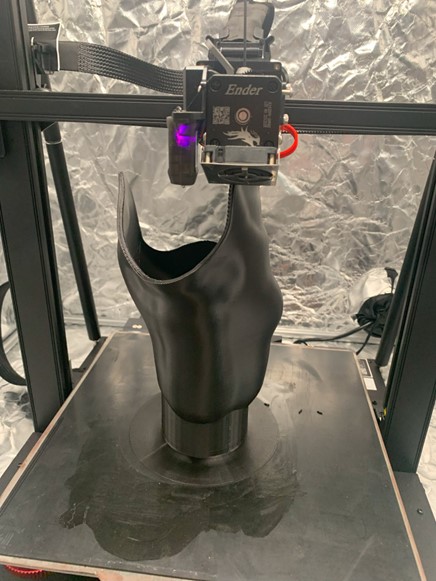

Ugani Prosthetics has developed a straightforward workflow for creating high-quality, affordable prosthetics and orthotics using 3D technology. This workflow has been utilised in various prosthetic workshops worldwide to produce devices.

Ugani is seeking to partner with prosthetic workshops within this network to bring this technology to their patients. Patients will benefit from high-quality, low-cost, fast, durable, and comfortable devices. - Full Description

-

Ugani Prosthetics is a Belgian company with a clear mission: to ensure that every amputee has access to high-quality, affordable prosthetics. To achieve this, Ugani has developed an innovative 3D workflow that leverages open-source software, tabletop printers costing just €2,000 instead of the traditional €200,000, and a standard iPhone as a scanner, which costs €300 instead of the typical €10,000. This efficient approach enables us to produce a prosthetic socket for less than €40, a fraction of the cost associated with traditional methods.

This 3D workflow has been refined and successfully implemented in various regions around the world, including Kenya, Nepal, and Malaysia. Now, Ugani is seeking global partners who are interested in adopting this workflow in their workshops. The goal of these partnerships is to help more patients gain access to the high-quality care they need, while simultaneously reducing costs, speeding up processes, and enhancing the overall quality of patient care.

By forming international partnerships, Ugani aims to extend its reach and impact. In countries where reimbursement systems are underdeveloped or nonexistent, the reduced cost of a prosthetic socket means that more patients can afford the prosthetics or orthotics they need. In other regions, where such systems may be more established, the lower production costs allow workshops to either focus more resources on patient care or increase their profit margins.

Ugani is particularly interested in partnering with workshops that are committed to implementing this 3D workflow to achieve these benefits. Through these collaborations, Ugani hopes to help more than 50,000 patients globally within the next five years.

Additionally, Ugani’s technology directly addresses the challenge of making high-quality prosthetics and orthotics more accessible to a broader population by significantly lowering production costs. This is achieved by simplifying the manufacturing process, reducing the need for expensive equipment, and providing comprehensive support to partner workshops.

As part of these partnerships, Ugani will offer continuous support through the Ugani Network Membership. This includes access to a detailed Wiki with all the necessary information for maintaining and using the equipment, as well as one-on-one support to ensure that the quality of the devices remains consistently high. - Advantages and Innovations

-

Ugani’s technology offers numerous advantages over traditional prosthetic methods and other 3D workflows.

Compared to Traditional Technology:

1. A prosthetist can take a scan and model a socket in under 30 minutes, enabling them to see at least 10 times more patients with Ugani technology.

2. Sockets can be produced for less than €40, which is at least 10 times cheaper than traditional sockets.

3. Ugani’s 3D sockets have been tested according to ISO standards and can be used for both test sockets and final sockets.

4. The workflow is clean and does not involve the use of plaster.

5. The workflow requires minimal space and equipment. All you need is a smartphone, a computer, and a 3D printer, instead of ovens, grinders, vacuum systems, and plaster rooms.

Compared to Other 3D Workflows:

1. Ugani is the only organisation offering a complete workflow — scanning, 3D software, and in-house printing. Competitors typically focus on just one aspect of the process.

2. Ugani allows you to stay in control by bringing the 3D printers directly to your workshop — no outsourcing, no dependency, and no hidden costs.

3. Ugani provides comprehensive training on how to use and maintain your 3D printers, ensuring they last for years and continue to produce high-quality prosthetics and orthotics.

4. You can become part of the Ugani Network, gaining access to all information, tips & tricks, lessons learned, and new innovations from Ugani.

For the past three years, Ugani has partnered with workshops around the world. We offer a unique combination of engineering and prosthetics expertise, essential for effectively integrating 3D technology into a workshop. Ugani aims to become the go-to engineering partner for every prosthetic workshop globally. - Stage of Development

- Already on the market

- Sustainable Development Goals

- Goal 12: Responsible Consumption and Production

- Goal 8: Decent Work and Economic Growth

- Goal 16: Peace and Justice Strong Institutions

- Goal 9: Industry, Innovation and Infrastructure

- Goal 3: Good Health and Well-being

- Goal 10: Reduced Inequality

- Goal 2: Zero Hunger

- Goal 1: No Poverty

- IPR status

- No IPR applied

Partner Sought

- Expected Role of a Partner

-

The partners which Ugani seeks, are already well established in their area and have a broad patient base. They already offer prosthetic and orthotic solutions to their patients, preferably also through reimbursement or insurance schemes.

The partner will continue to provide prosthetics and orthotics to their patients but will implement the Ugani 3D workflow in their workshop and use this to manufacture the devices. This will enable the partner to save time, energy, and materials, while reducing costs. This could result in either a lower price for the end customer or a higher profit margin for the partner. By adopting the Ugani 3D workflow, the partner will find their work becoming easier, faster, and more cost-effective.

The partner must be prepared to invest in this partnership and purchase the necessary equipment to begin producing prosthetics and orthotics according to the Ugani workflow. Ugani will then train the partner's staff on how to use the technology, after which the partner will be able to independently manufacture prosthetics and orthotics in a fraction of the time and at a lower cost than current methods.

The partner must ensure the proper reception and care of patients, as any workshop should. Additionally, the partner will be responsible for the quality and durability of the 3D-printed prosthetics and orthotics, which means they must closely adhere to the guidelines provided by Ugani.

-------

We are looking to build sustainable, long-term relationships focused on making prosthetics more accessible and affordable. Only companies that are committed to actively contributing to Ugani's overarching, sustainable goals are invited to respond. - Type and Size of Partner

- SME 11-49

- SME <=10

- Type of partnership

- Commercial agreement

- Investment agreement

Dissemination

- Technology keywords

- 3D printing

- Market keywords

- 05005015 - Orthopaedics

- Sector Groups Involved

- Health

- Targeted countries

- All countries