Summary

- Profile Type

- Technology request

- POD Reference

- TRGB20250512012

- Term of Validity

- 12 May 2025 - 12 May 2026

- Company's Country

- United Kingdom

- Type of partnership

- Commercial agreement with technical assistance

- Research and development cooperation agreement

- Targeted Countries

- All countries

Contact the EEN partner nearest to you for more information.

Find my local partner

General information

- Short Summary

- A UK SME is developing low speed turbine technology suitable for organic Rankine cycle (ORC) applications, in waste heat recovery, refrigeration etc. and is looking for an industrial partner to manufacture components. Type of cooperation: commercial with technical assistance, R&D.

- Full Description

-

Waste heat recovery (WHR) produces power from the heat that is the byproduct of many industrial and transportation processes. Users of WHR systems can reduce their power consumption significantly, increasing the efficiency of their processes. Waste heat is produced in large quantities in industry and transportation. In 2021 EU and UK industry produced 221 TWh of which 61% is in the temperature range of 100° to 200°C. The potential market for WHR systems is thus large. The maritime market is highly active now due to statutory requirements. Industrial take-up offers enormous potential that, for now, is restrained by the pay back period of the capital expenditure.

A temperature range of 100° to 200°C best suits power extraction via an Organic Rankine Cycle (ORC). An ORC system comprises heat exchangers, a pump and a turbo-generator, the last of which is typically the most expensive sub-system. For ORC systems up to about 200 kW power output the turbo-expander is typically a radial turbine that is connected to a high speed alternator or a synchronous generator via a gearbox. Both add cost and complexity. Above about 200 kW it becomes feasible to use a multi-stage axial turbine and connect it directly to a synchronous generator. Such small axial turbines are relatively expensive as they comprise multiple rotor discs.

With the aim of reducing the cost of ORC turbo-generators a UK SME has designed a turbine based on the principal of the “Elektra” steam turbine that employs a number of stages of expansion through a single bladed wheel to allow high efficiency operation at relatively low shaft speed. The multi-stage operation is of “pressure compounded” style whereby each expansion occurs at low flow incidence, thereby minimising blade pressure loss. The entry and re-entry of the working fluid is radial in nature, alternating between radial inflow and radial outflow, allowing all aerodynamic passages to be 2D in form and amenable to redesign for different duties and working fluids with changes to few components.

Its power/speed performance characteristic make it suitable for driving an asynchronous generator in a hermetic turbo-generator package, without a gearbox, that can be designed for output powers in the ~10kW to ~200kW range. It can also be produced as a standalone turbine, for connection to a separate synchronous generator, that can be designed for output powers in the ~200 kW to ~1MW range.

The turbine passages can be designed for use with most working fluids including liquid water, particularly in low flow, high head applications.

The turbine will be tested at TRL-4 during 2025 under a KTP programme as proof of aerodynamic concept. The first lab test results are forecast for July.

The UK company now has a European lead customer in the maritime market.

A manufacturing partner is being sought to progress the turbine to TRL-7 via joint development, part funded by EU or bilateral funding schemes. The UK company has outreach to the UK market but not much further. During a successful development project, commercial agreements will be sought between the partners to collaborate on future manufacturing and commercialisation. - Advantages and Innovations

-

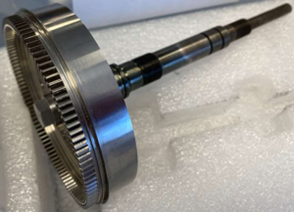

• The turbine comprises a single blisk and two stationary plates in which the gas-paths are of 2D forms, thus not requiring 5-axis machine tools.

• No need for exotic metals.

• Thrust is naturally low without the need for a balance piston.

• The turbine’s relatively low speed at low power avoids the need for a gearbox prior to generator connection. For power output above ~200kW it can be connected to a synchronous generator where the alternative turbine would be a multi-stage axial turbine. - Technical Specification or Expertise Sought

-

• Experience in manufacturing or sourcing of turbomachinery products (see the Pictures for guidance).

• Experience in manufacturing or sourcing of alternators.

• Knowledge of power system integration.

• Knowledge of turbo-generator packaging (including control system).

• In-house mechanical design, manufacturing, electrical and packaging engineers able to support the joint development of the product.

• Facility to carry out development and pass-off testing. - Sustainable Development Goals

- Goal 7: Affordable and Clean Energy

Partner Sought

- Expected Role of a Partner

-

Type of partner sought: industry

Specific area of partner sought: manufacturers of energy industry components.

Role of partner sought: The Partner should be a manufacturer able to productionise the turbine and integrate it into a higher-level system, likely to be the Turbo-generator package. The partner could be a Turbo-generator manufacturer or system integrator.

The Partner should be experienced in obtaining development funds from the EU or national funding schemes.

The Partner should be market aware and be able to drive the product strategy to complement the UK SME’s outreach to the UK energy market. - Type and Size of Partner

- Big company

- SME 50 - 249

- Type of partnership

- Commercial agreement with technical assistance

- Research and development cooperation agreement

Dissemination

- Technology keywords

- 04005009 - Energy from wastewater

- 04005012 - Waste to energy - other

- 04005007 - Waste incineration

- Market keywords

- 06006003 - Heat recovery

- Targeted countries

- All countries