Summary

- Profile Type

- Technology offer

- POD Reference

- TOTR20240711020

- Term of Validity

- 16 July 2024 - 16 July 2025

- Company's Country

- Turkey

- Type of partnership

- Research and development cooperation agreement

- Commercial agreement with technical assistance

- Targeted Countries

- All countries

Contact the EEN partner nearest to you for more information.

Find my local partner

General information

- Short Summary

- A University in Turkey has developed a multi-stage vehicle spring system, featuring leaf springs with varying stiffness rates made from fiber-reinforced composite materials. This system is approximately 75% lighter than traditional steel leaf springs. The technology is at TRL 5 and can be applied to various vehicle types (road and railway). The technology is primarily aimed at automotive manufacturers looking for advanced suspension solutions. Technical cooperation and Licensing is preferred.

- Full Description

-

This multi-stage spring system addresses several key challenges in vehicle suspension technology. The weights of the components that are not carried by the suspension system in vehicles are defined as "unsprung mass", and the leaf spring suspension system itself is included in this class. Traditional metal leaf springs used in heavy vehicles are known to contribute significantly to the vehicle's unsprung mass, affecting ride comfort and performance. This invention reduces unsprung mass by using fiber-reinforced composite materials, which are lighter and more resistant to environmental factors such as thermal loads and corrosion. Unlike conventional systems that respond uniformly to road inputs, this system adjusts its response based on the severity of road conditions, providing optimal comfort and stability.

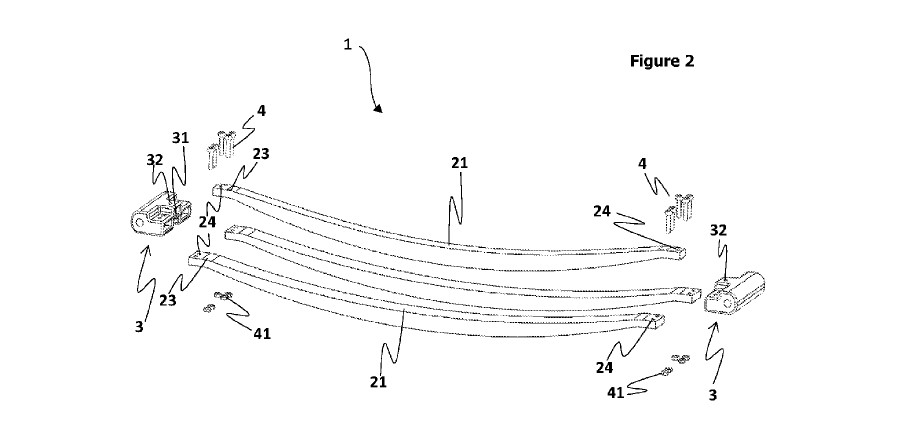

The patented composite spring system features multiple leaf springs, each with different stiffness rates, arranged side-by-side rather than vertically stacked. This arrangement reduces friction and wear, enhancing durability and performance. The system operates gradually, adjusting to the magnitude of road inputs, providing a smoother ride under various driving conditions.

Key features and specifications include:

- Material: Fiber-reinforced composite

- Leaf Spring Arrangement: Side-by-side positioning along the horizontal axis (-X/+X)

- Variable Stiffness Rates: At least two different stiffness rates

- Environmental Resistance: Better performance under thermal loads and corrosion

Weight: Approximately 25% of the weight of steel leaf springs

Applications include various road vehicles, from passenger cars to heavy commercial trucks even do scalable to train, offering significant improvements in suspension system efficiency and vehicle handling. - Advantages and Innovations

-

This multi-stage spring system's innovativeness lies in its ability to provide variable stiffness, which is not commonly found in traditional leaf springs. The use of composite materials further enhances the system's durability and performance under diverse environmental conditions.

- Adaptive stiffness improves ride quality and vehicle control.

- Reduced weight contributes to better fuel efficiency.

- Increased durability and reduced maintenance costs.

- Environmentally resistant materials reduce wear and enhance lifespan.

The patented technology is suitable for reducing weight in electric cars, trucks, last-mile delivery vehicles, wagons, trams, metro cars, and similar applications. - Stage of Development

- Lab tested

- Sustainable Development Goals

- Goal 9: Industry, Innovation and Infrastructure

- IPR status

- IPR granted

- IPR notes

- WO2022066132A1 - A multi-stage spring system suitable for use in vehicles

Partner Sought

- Expected Role of a Partner

-

The university seeks partners in the automotive industry, railway vehicle manufacturers, and OEM manufacturers for technical cooperation to further develop and adapt the technology to specific market needs.

Additionally, licensing agreements are sought with manufacturers interested in integrating this advanced suspension system into their vehicles. Partners are expected to provide technical expertise and market access to facilitate the adaptation and commercialization of the technology.

Technical Cooperation Agreement: Collaborate on further development, customization, and integration of the suspension system into various vehicle platforms. - Type and Size of Partner

- SME 50 - 249

- SME 11-49

- R&D Institution

- Big company

- Other

- Type of partnership

- Research and development cooperation agreement

- Commercial agreement with technical assistance

Dissemination

- Technology keywords

- 02007005 - Composite materials

- 02009012 - Automotive engineering

- Market keywords

- 08001009 - Speciality/performance materials: producers and fabricators

- 09001005 - Motor vehicles, transportation equipment and parts

- 08003007 - Other industrial equipment and machinery

- 08001004 - Fibre-reinforced (plastic) composites

- Sector Groups Involved

- Mobility - Transport - Automotive

- Aerospace and Defence

- Targeted countries

- All countries